Home

Introduction

This document is intended to give you an outline of what to considering at an early stage in the project, in terms of OrderFlow configuration requirements. At this point, we do not need formal responses to the questions provided. Requirements will be captured in detail during the project Requirements Gathering phase, and recorded in other documents and Redmine tickets.

Environment Setup

The degree to which you will need to set up a physical warehouse environment will depend on whether you are setting up a completely new warehouse that will be managed by OrderFlow, or choosing OrderFlow to replace your current Warehouse Management System (WMS). In the latter scenario, our main task will be one of data migration. This chapter assumes the former scenario.

Note that if you have chosen us to host your OrderFlow instance, we will of course provide support for that server. Apart from that, we are not responsible for the setup or support of the hardware or network in your warehouse. However, we can provide you with a set of recommendations on how you should set up your warehouse and IT infrastructure to support an optimally running instance of OrderFlow.

Requirements

OrderFlow Desktop is accessed using a web browser that will run on most PCs or tablets. The officially supported browser is Mozilla Firefox. However, OrderFlow successfully runs on all major PC-based browsers. Our Handheld application is also a browser-based application that is designed to work with the vast majority of handheld devices.

We can accomodate most warehouse set-ups, but the configuration and capacity of the hardware to support OrderFlow depends on your warehouse layout and throughput. We need the following information so we can advise you how to proceed:

- Warehouse layout

- Average number of orders processed per day.

- Maximum number of orders processed at any one time.

- Whether you will be using paper or handheld task picking (see the Picking and Packing chapter for more details).

Networking

OrderFlow must be connected to a network. If you are using only OrderFlow Desktop (accessible via a web browser), a LAN network is sufficient. OrderFlow normally runs in the 'cloud' over a secure connection, so your warehouse firewall will need to be configured to allow outgoing connections from your warehouse to OrderFlow.

Your warehouse LAN network will need to be configured to allow for incoming support requests.

If you have chosen to use our Handheld application, a WiFi set up is required.

Handheld Terminals

If you plan to use handheld terminals, these will need to be procured if you do not already have a usable supply. We don't supply handhelds ourselves or mandate the use of specific devices. However, brands we have worked with most in the past include Motorola, Datalogic and Touchstar. We can put you in touch will suppliers on request.

Once you have identified a candidate handheld terminal device, we recommend that you verify this against the OrderFlow handheld application before placing a bulk order. Your handheld device supplier will help you with the configuration.

Our handheld screens are designed to work with a minimum screen size of 240 x 320 pixels, but generally the bigger the screen the more usable they are. Aside from that, OrderFlow will work fine with any WiFi enabled warehouse handheld that can support the passing of input from a built-in barcode scanner to the web browser.

Occasionally we encounter old handhelds that won't automatically take the input from the built-in scanner, add an automatic 'return' and pass it to the browser. If it doesn't work by default the fix usually involves installing 'wedge' software that will intercept the output from the scanner and pass it to whichever element in the web page has the focus. It may be worth getting your supplier to configure this in the standard build the devices use when rebooted.

You should ensure that when the device is cold booted it automatically:

- Connects to your WiFi network and is able to connect to the internet.

- Has the OrderFlow logon page defined as the default browser home page.

- Automatically passes barcode values into which field has the focus within the browser when a barcode is scanned.

We have occasionally encountered problems with WiFi 'deadspots' and/or 'dropouts' when sessions were transferred between repeaters. Both these issues related to the age of the firmware in the handhelds. WiFi performance is known to be better in environments using more modern devices that have up-to-date drivers, firmware and browsers. The ideal setup is to have the same company responsible for supporting both your handhelds and the WiFi infrastructure.

If you have a mix of handheld devices in the warehouse you may find the optimal font or text size varies between devices, particularly if they have different screen sizes. The OrderFlow administrator is able to define device specific CSS files for the handhelds and use the browser user agent value to determine which CSS should be used for each of the different device types.

Packing Desks

A typical packing desk is a networked PC running the Desktop configuration of OrderFlow on the Microsoft Windows operating system. The number of packing desks you require will depend on your warehouse operations.

Goods in/Returns

If other processes, such as Goods In or Returns, are handled in a different part of the warehouse, you may require a separate machine running OrderFlow for these.

Administrative Tasks

You may wish supervisors to have access to seperate machine running OrderFlow, in order to carry out administrative tasks.

Printers

Every packing desk must be connected to a laser printer (for despatch notes) and a thermal printer (for courier labels).

If you are using paper-based task picking (as opposed to handheld picking), you will need at least one high volume laser printer in order to print out the picking notes.

For more details as to how to configure an OrderFlow workstation and printer, please see our Printing and Workstation Setup Guide.

Warehouse PC Support

Although we do not support warehouse PCs or printers, we do support their interactions with any Realtime Despatch software that you have running locally, in particular for managing print jobs.

So that we can support you effectively, we recommend that you install TeamViewer on each local PC that you wish to be supported. Without TeamViewer providing us with remote access, supporting printing issues can be extremely difficult and time-consuming.

Warehouse Design

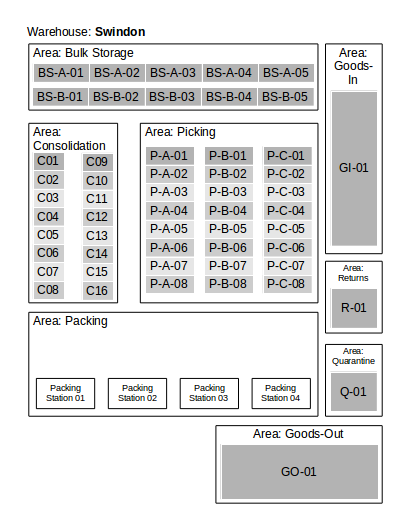

A typical OrderFlow instance has one site, sub-divided into areas, which are further sub-divided into locations.

Sites

OrderFlow can support a multi-site environment. Each site is typically a distinct building or geographic location. Channels, users, processes and business rules can be specific to sites. Most warehouse processes run within a site, although OrderFlow supports bulk stock movements between sites.

- How many sites should your OrderFlow instance support?

- How should OrderFlow determine what orders should be processed by which site?

Areas

OrderFlow can assign a collection of locations to a specific area. Areas are typically used to scope stock checking activities.

Locations

In order to configure OrderFlow so that it correctly reflects your warehouse design, we need specific details from you on the locations in your warehouse that correspond to the following OrderFlow location logical types:

- Incoming locations (i.e. for deliveries)

- Storage locations - bulk and pickable

- Locations that will be associated with specific OrderFlow workstations (if required)

- Consolidation locations

- Quarantine, Frozed and Damaged stock locations

- Mobile locations (for handheld picking only)

An example warehouse layout using these types is shown below:

We also need to know the physical type of each of these locations, for example:

- Pallet

- Shelf

- Carton

- Tote

- Cart

- Trolley

- Forklift

This becomes particularly important if you wish to tie the storage of specific types of products to specific location types.

Further, we need to know how you intend to use these locations. For example:

- Do you wish to have separate bulk storage and replenishment locations?

- Do you wish to use consolidation locations for cross-docking?

- Do you wish to optimise your routing through storage locations using a sort indicator, or an alternative type of routing?

- Do you wish to assign a relative value to different picking locations? For example, high value locations might be those that are more easily accessible.

Once we understand the layout of your warehouse, we can assist you in populating warehouse configuration spreadsheets, which can be used to upload your warehouse areas and locations onto your new OrderFlow instance.

Location Labelling

Once you have uploaded your warehouse locations, you will be able to use OrderFlow to print your location labels.

We will need to know whether you would like to use this facility. If so, you will be able to choose from a set of preconfigured location label generating reports. Alternatively, we will be able to create a customised label that matches any specific requirements you may have.

Site, Channel and Organisation Scope

Many OrderFlow functions can be scoped to specific sites, channels or organisations, meaning that OrderFlow can be configured to behave differently depending on the site, channel or organisation it is working with.

A site represents a specific warehouse, which may be an actual building, or section of a building, where certain order types are processed. An example of site-scoped behaviour is that OrderFlow can print different returns addresses on the despatch note.

A channel represents a specific eCommerce system (for example, Magento) that sends orders to OrderFlow. An example of channel-scoped behaviour is that OrderFlow can handle all orders that are imported from a specific channel as a priority, or select a special courier service for orders placed on that channel.

An organisation represents a company, which can have one or more channels. An example of organisation-scoped behaviour is that OrderFlow can use different logon credentials when getting a label from a Courier system.

Typically, for a retailer, there will be one organisation associated with multiple channels on OrderFlow. As a minimum, there must be at least one site, organisation and channel configured. For a 3PL, initially we may set up a test organisation and channel, which will be activated as soon as they are ready for Go-Live.

- How many sites, organisations and channels do you need to be configured on OrderFlow?

- What are their names?

- What is the address of each site?

eCommerce Systems Integration

We provide built-in integrations for a number of different eCommerce systems including Amazon, eBay, Magento and Shopify, as well as accounting and ERP systems such as Sage 200.

Integration with eCommerce Systems

OrderFlow has the capability to import the various types of data from an eCommerce system. The most commonly received are:

- Products

- Orders

- Purchase orders

A typical integration enables OrderFlow to notify an eCommerce system of the following events:

- Stock changes and end-of-day inventory levels

- Shipment events such as when a shipment is packed, despatched or split

- Deliveries and delivery lines applied

- Purchase orders completed

- Products activated

- Returns applied

Please consider:

- What specific eCommerce systems do you need OrderFlow to integrate with? Integration with an eCommerce system that is new to OrderFlow may require additional development.

- How many OrderFlow sales channels do you require? Typically there is a different channel for each eCommerce system that supplies OrderFlow with orders.

- If you will be using our built-in integrations, do you have any requirements beyond our standard import and notification offerings, above?

- Which system should be the inventory master? This is usually OrderFlow, but some customers use third party systems such as Sage.

- Will the products and orders imported into OrderFlow be provided by the same eCommerce system, or different ones?

- If you are using sales channels such as Amazon and eBay, where the order details are not supplied in real-time, there may be a risk of over-selling stock. What stock-level threshold should be in place on OrderFlow to avoid this?

- Do orders from different sales channels require different paperwork, courier or batch selection logic?

- Do you have the contact details for each eCommerce provider if a problem is identified with a sales channel, in or out of standard business hours?

Order Import

OrderFlow imports specific order data fields from the third-party system and maps them to Orderflow data fields. In addition to order line details, other data include:

- Billing and Shipping Address

- Gross and Net Price

- Barcode

- Weight

Orders should be validated by the sales channels prior to import, however this cannot be relied upon for the key data elements that are required by OrderFlow to process an order. Please consider:

- Do you require additional data fields to be imported over and above those provided as standard by OrderFlow? For example, you may want a 'gift' flag to be used to omit pricing from the recipient paperwork.

-

What data fields are mandatory, and what validation should be put on the content of incoming order data, for example:

-

Should it ever be possible to receive an order without any line items?

- Should it ever be possible to receive an order for a product that is not defined in the warehouse?

- Should OrderFlow reject UK orders without a delivery postcode or draw them to the attention of Customer Service?

Alternatives to Full Integration

Where a full system integration is not available, the file import and export options allow for the necessary information to be exchanged in bulk using CSV (comma-separated variable) text files, or even Microsoft Excel Spreasheets.

OrderFlow has an advanced file mapping capability that allows product and order data to be received in virtually any text-based file format.

This option may require some manual operator intervention on a daily basis, with users periodically generating files containing updated product definition or lists of orders that have been received and need to be fulfilled. However, in some cases it is possible to automate the export of these files and their import into OrderFlow.

An important integration requirement involves notifications on shipments despatched as well as stock levels for products. OrderFlow can be configured to general despatch and inventory reports that would be suitable for import into various external systems. These reports can be configured to automatically be sent to third parties using email, HTTP, or be posted to a remote file server using FTP.

Products

OrderFlow can support numerous products types, and can be configured to process certain product types differently. Some product types currently supported by OrderFlow are:

| Type | Description |

|---|---|

| Default | The default product type. Typically these are physical products that can be stored, and go through all of the standard fulfilment processes. |

| Batch Tracked | Associated product lot references, useful if there is requirement to identify source batches for products received or despatched. |

| Bundle | A grouping of individual physical products (SKUs) which can be sold and despatched as a logical unit. |

| Composite | Created or assembled using one or more non-sellable constituent raw component products. |

| Free Gifts | Does not require picking, but can be scanned to pack and will appear on customer paperwork. |

| Insert | Does not require picking, but can be scanned to pack and will not appear on customer paperwork. |

| Packaging | A stockable packaging product, for example, a jiffy bag or cardboard box. |

| Raw Component | A non-sellable component which forms part of a composite product, for example via a kitting or assembly process. |

| Virtual | Usually a product with no physical form that does not participate in stock management operations, for example a downloadable application. |

We need to know the type of every product that you intend to despatch from your warehouse, and any workflow requirements associated with these types.

In the most simple cases, your warehouse will be storing and despatching default products using 'standard' fulfilment processes.

Some further aspects to consider:

- Do all of your sales channels use the same product code to identify an individual product?

- Do any of your products require an element of personalisation?

- Are datasheets (product-specific printable documents) required for any of the products you ship?

- Are products with the same SKU interchangeable, or are there factors such as remaining shelf life, condition or size which mean that interchangeability cannot be guaranteed?

- What is the threshold level that should trigger the re-ordering of a product?

- Do you wish to use product attributes - such as those listed in the Integration chapter - to determine your courier selection script?

- Do you wish to use product attributes to determine your target putaway locations?

- If the answer to the previous two questions is yes, please consider if those product attributes should be made mandatory, and where OrderFlow should get these attributes from (for example, the eCommerce system, or via an uploadable product catalogue spreadheet)

You should also consider how you would like to identify your products.

- Do you wish to relabel products using your own barcodes, or rely on barcodes provided by customers?

- If so, do you have any special requirements on what information appears on your product labels?

Goods-in and Putaway

Your goods-in and putaway requirements for OrderFlow depend on how closely your instance of OrderFlow should be integrated with your accounting or ERP system. For example, some customers require purchase orders to be imported into OrderFlow (from systems such as Sage) before deliveries can be accepted into the warehouse.

The processes that will be most suitable to use will depend on a variety of factors, including the nature of products received, the layout of your warehouse, and the knowledge/capability of your workforce.

Goods-in

- Will you be using a third-party Purchase Order or ASN system to manage deliveries?

- Do you require Desktop or Handheld-based processing of deliveries?

- Do you use any form of cross docking, or does every delivered item go straight to stock?

- Are deliveries processed immediately on receipt into the warehouse, or is there typically a few hour lag before this happens?

Putaway

- Do you wish to use the OrderFlow goods-in delivery process to put away to stock, or a separate putaway process?

- Can incoming SKUs be put away one at a time or should putaway be a two stage process that scans items into a cart and allows a user to put away the contents of the cart in a separate operation?

- Do you wish each putaway item to be scanned separately, or simply mark the delivery as putaway once, at the end of the putaway process?

- Do you wish OrderFlow to suggest putway locations, or should a user select them manually? If the former, what rules should OrderFlow use to select locations?

- Are deliveries typically received in mixed pallets or totes that require sorting before they can be put away efficiently?

Recommendation

During the requirements gathering phase we recommend a dedicated session (using a TeamViewer demonstration) to explain the system options available for receipt and putaway, and to match these against your business requirements.

Order Processing

Typically, an order imported into OrderFlow will be processed as follows:

- One or more shipments will be created for the order.

- Stock in the warehouse will be allocated to each shipment.

- A courier and service will be selected for each shipment.

- Each shipment will be assigned to a batch.

- A batch of shipments will be picked, packed and despatched.

Apart from the picking and packing activities, all of the above steps are performed automatically by OrderFlow, with no manual intervention required by warehouse staff. However, some customers may require all or a subset of their orders to be processed differently.

Is there any way in which your desired process for some or all orders differs from the standard OrderFlow offering, above?

Note

During the requirements capture phase we can provide detail on types of workflow options that are available in OrderFlow to address specific issues you may be facing.

OrderFlow is also a priority concept which allows for certain orders to be fast tracked through the processing.

Do you wish to support setting a higher priority for certain shipments? Please think about the rules you would wish to apply in determining whether a shipment should be considered 'high' priority.

Stock Allocation and Assignment

After order import, OrderFlow will automatically create a shipment and allocate and assign stock to that shipment.

- Do you require a deviation from this process? For example, would you like certain order types to be allocated stock manually?

- By default, available stock is assigned to the oldest order first. Do you require high priority orders to be treated differently?

Out-of-stock Items

OrderFlow can be configured to split-off out-of-stock products or order lines into a separate shipment to be processed when the stock becomes available. This enables you to immediately pack and despatch the in-stock items for the original shipment.

- Should out-of-stock orders raise an OrderFlow alarm?

- Do you wish to split-off out-of-stock products or order lines into a separate shipment?

- If so, are you happy to use our default back order splitting strategy, or do you require us to create a bespoke one?

We are in the process of extending our functionality to handle out-of-stock items. Please discuss your requirements with us.

Replenishment

If you use product-specific picking locations and/or non-pickable bulk storage locations, you will require some sort of replenishment process on OrderFlow.

- Do you wish to use a background replenishment process to maintain pickable stock for certain products and specified levels?

- If you use an OrderFlow background replenishment process, what is the cut-off stock level in your primary picking locations that will trigger that process?

- Alternatively, are you happy to rely on priority replenishment, which allows for picking location replenishment only when required for shipments awaiting despatch.

Picking and Packing

Each of our customers vary in their approach to distributing effort across the picking and packing processes. For example, picking a large batch into a mixed tote will require more sorting at the Packing stage, while picking smaller batches into sub-divided carts requires more frequent Picking activities. OrderFlow can accommodate numerous picking and packing strategies.

Picking

OrderFlow's default picking method is batch-based picking. Batch based picking allows shipments that can usefully be grouped together to be associated with the most appropriate pick and pack process, for example:

- 50 single line shipments for small items that can all be picked from the mezzanine

- 200 shipments, each for the same SKU

- 20 multiline, high priority shipments

- 20 multiline shipments which each include at least one item that requires a forklift to pick

If you are using batch-based picking, then OrderFlow will automatically assign a shipment to a batch based on a set of criteria, supplied by you. Typical criteria include:

- Shipment priority

- Shipment destination

- Courier and service selected

- Number of order lines in the shipment

- Number of items in the shipment

- Picking location

We will supply you with a template outlining the information we need from you. This will enable us to write a batch selection script that will automatically group shipments prior to picking.

Alternatives to Batch Picking

Alternatives to batch-based picking that we can accommodate are:

- Individual shipment picking

- Picking via consolidation

- Interleaved task picking

Please ask us if you require more detail on each of these alternatives.

Recommendation

We can talk you through in detail the options available at any stage in the process. However, we recommend you start with a simple picking strategy, then refine these after launch to maximise efficiency gains.

Handheld Picking

If you have chosen to use our Handheld application, we need specifics on the mobile picking locations you intend to use:

- Do you wish to pick to a single cart, or a sub-divided cart, as illustrated below?

- Is the size and weight of your stock relatively homogenous, or do you need OrderFlow to select mobile picking locations based on product size and weight?

Short Picks

For a well managed warehouse short picks (where stock cannot be found in the expected location) are rare. OrderFlow is nonetheless flexible in its handling of short picks. It can:

- Initiate a stock adjustment

- Eject the shipment from the batch being picked

- Split off the out-of-stock items into a separate shipment during the pick process

Other options are likely to be introduced in the future.

- How do you want OrderFlow to handle short picks?

Packing

OrderFlow's default packing method is scan-to-pack, meaning that every item being packed is scanned by a user at the Packing Station. Once all the shipment items are scanned, the user can mark a shipment as 'Packed' and print out the despatch note, label, and any other required documents (such as customs documentation). The paperwork OrderFlow provides is highly configurable depending on your needs. See the Paperwork chapter for more details.

Alternatively, OrderFlow can accomodate packing processes where there is no scanning of individual items for a shipment in a batch. For example, entire batches can be manually marked as 'Packed' by the user once packing of every shipment in that batch is complete.

Further, some customers require OrderFlow to capture and validate the packaging details when scanning items to pack, as some couriers require specific packaging types.

Please discuss your specific packing needs with us.

Integration with Courier Systems

We need to know what couriers and services you will be using to ship your orders.

- Which couriers do you intend to use at launch, which services do you intend to use?

- Do you intend to ship internationally, outside of your customs zone (e.g. EU)?

Important Note

We need to know early on the project life cycle what courier integrations are needed at launch. If an integration is required at launch but not available, there may be cost and timing implications for the project.

Most of our customers have direct relationships with couriers. Some use third party Delivery Management systems such as Hypaship, MetaPack, NetDespatch, Abol or Huxloe. OrderFlow can accomodate both.

- Do you have the contact details for each courier if a problem is identified with a courier service, in or out of standard business hours?

Courier Selection

OrderFlow automatically sets the courier and service for a particular shipment based on instructions received from the sales channel or a set of criteria, supplied by you. This process will run automatically before a shipment starts the picking process.

Typical criteria our customers provide include:

- Postal address

- Priority

- Price

- Product attributes such as weight, size, fragility and type

We will supply you with a template outlining the information we need from you. This will enable us to write a courier selection script that will run automatically whenever a shipment is created. If you require any deviation from this process - for example, if you wish users to select the courier and service manually - please let us know.

Returns

How returns are handled depends on your returns authorisation process. OrderFlow can be configured so that a return cannot be processed until the original order number is entered.

Recommendation

During the requirements gathering phase we recommend a dedicated session (using a TeamViewer demonstration) to explain the system options available for returns, and to match these against your business requirements.

- Do you wish to process returns without an original order number?

- Are your returns initiated by a third party system?

- Do you wish Customer Service and/or a third party system be notified of a return?

- Do you wish OrderFlow to capture and store any details on a completed returns form?

- What additional information should the user recording the return be able to capture?

-

What are the different returns outcomes that each item might be routed to, for example:

- Return to stock

- Destroy

- Hold for inspection

- Return to manufacturer

- Charity

-

Do some returned items need to be sorted by manufacturer when they are stored?

Paperwork

From an OrderFlow perspective, paperwork mainly consists of despatch notes or invoices that are added to the package before despatch, but may also include customs documentation, labels customised for particular workflows or labels enhanced with marketing information.

For despatch notes, customers usually provide us with a PDF document that represents how they want their paperwork to look. Other requirements to consider:

- Do you want information about other shipments on your paperwork? For example, split-off shipments to handle out-of-stock items?

- Do you need your paperwork to support multiple languages?

- If you are performing paper-based batch picks, would you like the paperwork to be printed at the packing desk, or as part of the batch print before picking?

- Do you have any requirements for integrated stationary? For example, peel-off courier labels to be included on the despatch note?

- Do you require returns information or even a returns form to be included as part of your despatch documentation?

- Do you have any customs documentation needs? For example, if you are shipping outside the EU, you will need a CN22 form, detailing the value, weight and the harmonised system code for each item.

- Can all your required paperwork variations be printed on the same paper stock using the same printer?

Reporting

OrderFlow has numerous built-in reports including Warehouse, Periodic and Location reports. We also have built-in Dashboard reports as part of our user interface. You will have the opportunity to review these when your vanilla instance is up and running.

OrderFlow can also be configured to periodically generate and send out reports as well as notifications of errors or unusal events (alarms) on the system. OrderFlow also allows for the creation of custom reports and dashboards to cater for virtually any reporting need.

Some questions to consider:

- Do you have any additional reporting requirements?

- Would you like to see different dashboard reports for some or all of your users?

- Should access to some reports be limited to particular roles?

- Do you need to send out end of day reports to third parties or even members of your organisation. If so, where would you like your end-of-day reports sent? For example, we can provide these in an email or email attachment.

- Who should OrderFlow send alarm-generating periodic reports to?

Recommendation

Having an in-house technical staff who can be trained to use OrderFlow reporting features can be very beneficial in ensuring that you get the most from the system in terms of information and visibility of operations.

User Roles and Access

OrderFlow user access is highly configurable, meaning that you can restrict users to specific roles, screens and sub-menus. It is important that each OrderFlow user - including temporary contract staff - is given a unique logon that can be used to identify them, for security and traceability reasons. The ability to create and modify user access is an obvious security risk, and therefore should be entrusted to a small number of permanent employees in your organisation. The OrderFlow Advanced tab has the functionality to drastically change your OrderFlow configuration and underlying data, so access to this tab should be restricted to IT-literate users with an administator role.

Some typical user roles are as follows:

- Batch Handler

- Picker

- Packer

- Stock Checker

- Returns Handler

- Warehouse Administrator

-

Warehouse Read Only

-

What types of user roles do you wish to be created for your OrderFlow instance?

- Who in your company should be assigned those roles? Note that a user can have more than one role.

If your organisation is a large one, with numerous OrderFlow users, we can arrange for user data to be imported via a spreadsheet.

A user cannot be logged onto more than one instance of OrderFlow at the same time. However, the same user can be simultaneously logged on to both the OrderFlow Desktop and Handheld applications.

Handheld Security

When the Handheld application is used for most of the operational processes, many of the users may be temporary staff who will be trained only to perform specific operations. One option is to set up a administrator pin number which will need to be entered each time a handheld operator needs to be make a stock correction. If all of your users are well trained and trusted staff, then this option may not be necessary.

Please consider whether you would want this option enabled.

Housekeeping

As your business expands, housekeeping of old data will be essential to ensure that OrderFlow continues to operate efficiently, even when your data volumes grow.

Typically, we distinguish between Logging data - such as error logs, system performance logs and schedule execution logs, which could be deleted after a brief period of time - and Operational Data such as orders, shipments and stock change records, which must be retained for a longer period.

Of the Operation Data, some of this may be regarded as being higher value.

- What data is essential to you and how long should it be accessible on OrderFlow?

- Do you have any requirements for your data to be archived onto a third party system (for example, backup tapes)?

- Do you have any plans for using a Data Warehouse to perform detailed analysis on historical data.

Requirements Note

During the requirements gathering stage we will present to you a specific proposal covering rules for data retention on the system. We would require sign off during the pre-launch implementation.

Additional Features

OrderFlow has a number of add-on modules that you may find helpful in optimising your warehouse operation. Some of our currently available modules are:

- Billing, User Activity and Productivity Tracking modules

Each of these modules provides statistics on a specific set of metrics, specified by you, to help you monitor and manage activity in your warehouses. The Billing module is particularly useful to our 3PL customers.

- Advanced Stock Checking module

This module provides considerably more functionality than our basic Stock Checking module. You can assign and desassign users to specific activities, monitor an activity's progress in real time, and specify key performance indicators to help you optimise the scope and frequency of your stock checking activities.

We will demonstrate each of these modules to you, and discuss any bespoke developments required to meet your business needs.