Warehouse Management¶

OrderFlow has user-friendly Inventory and Warehouse functions which make it easy to manage stock in an efficent and cost-effective way.

Stock can be placed in any number of different locations in a warehouse. In OrderFlow, these locations can be configured to be of various types that allow for fine-grained usage and control. For example, locations such as shelves, pallets, picking carts, totes, fridges, consolidation ‘pigeon holes’ (and so on) can all be created.

Locations can be assigned to areas within a warehouse, to allow for easy compartmentalisation of the available warehouse space. For example, locations can be defined as picking locations, bulk storage locations or quarantine locations.

This chapter describes how OrderFlow manages the stock in locations, and how it makes such stock available for various warehouse operations.

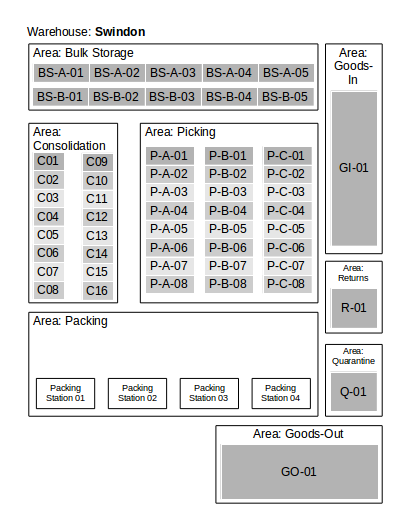

The diagram below shows a simple example warehouse layout, using OrderFlow terminology. The shaded areas denote locations.

Terminology¶

Throughout this chapter, reference will be made to sites, areas and locations. The relationship between these is as follows:

- A Realtime Despatch customer will have one or more sites; a site typically being an individual warehouse.

- A site is made up of one or more areas.

- An area is made up of one of more locations.

Locations¶

A location is simply a defined place in a site where stock can reside.

Locations can be configured to hold stock for just a single product, or they can be configured to contain units of multiple products. OrderFlow enforces such restrictions throughout.

Locations can be configured to have a number of different attributes, such as aisle, bay, level, position, side, dimensions. They can also be given various indicators to allow them to be ordered in different ways for different purposes, such as picking, replenishment and stock checking. (More on this later.)

Locations are defined to be of specific Location Types.

Location Types¶

OrderFlow categorises locations into different types, to help it manage the flow of stock more easily. Location Types are configurable entities that can have any combination of various defined attributes. This allows for fine-grained control of how locations are used, particular to the specific customer needs.

There are many attributes of a location type - some commonly-used ones are detailed here:

- pickable: Determines whether this location can be used as a source location for picking operations. If stock is only in non-pickable locations, then replenishment of picking locations must occur before picking can proceed.

- storage: Indicates that the location can be used for storage. Only storage locations will typically be considered as target locations for putaway operations.

- multiProduct: Indicates that a location is designed to contain multiple products.

- incoming: Used specifically for locations for receiving incoming deliveries.

- damaged: Used to hold stock that is considered to be damaged.

- mobile: Used for locations which do not have a fixed physical position in the warehouse. Physically, may be a cart, cage, trolley, tote or some other mobile container. Used extensively in handheld scanner-based operations.

Products¶

Products are the shippable goods that are received into the warehouse via deliveries, stored in locations, and sent out in shipments following the receipt of orders into OrderFlow.

Products are usually counted in units and generally referred to as stock (when talking about physical instances of a product).

Products can be categorised according to physical attributes and also logically typed. For example, an ‘instruction manual’ product could be categorised as a ‘book’ of ‘default’ type, whereas a ‘tool kit’ product could be categorised as a ‘tool’ of type ‘bundle’.

Typical products types are:

- default: A sellable stock-based product, eligible for stock notifications

- virtual: A virtual product, for which no stock is held, but is sellable. No fulfilment for a product of this type is required.

- bundle: A bundle is sellable product which is composed of underlying (typically) stock based products. It is also a virtual product in the sense that there is no physical representation of the bundle, only the underlying constituent products.

Inventory¶

The term ‘inventory’ is used in OrderFlow to mean the overall view of the stock position, without going into detail as to exactly where that stock resides.

For example, if a product is held in differing quantities in many different locations in a warehouse, the inventory for that product would include the total number of units across all those locations.

The inventory would also detail how much of that total quantity was usable, (i.e. excluding any damaged or quarantined stock), and how many units of that product were required by pending order lines.

The available quantity can be derived as the usable quantity less the required quantity. Note that this can be negative if there is insufficient stock in the warehouse to fulfil all order lines for that product. (Such a negative amount is called the shortfall of a product.)

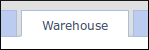

Tasks¶

Stock move tasks are used by OrderFlow to manage many warehouse processes. These are essentially instructions to move explicit quantities of products from one location to another. They are also used internally to drive certain processes.

There are many different types of tasks - some of these are listed here:

- putaway tasks: where stock is moved from incoming delivery bays to storage locations.

- replenishment tasks: where stock is moved from bulk non-pickable storage locations to pickable locations.

- picking tasks: the process of picking stock to fulfill orders, especially when using a handheld terminal.

- consolidation tasks: used when multiline shipments are routed into a consolidation area prior to packing.

When a stock move task is executed and applied, stock changes are created in OrderFlow. These are immutable records whose purpose is to preserve an audit trail of “what happened when”.

Warehouse Management Features¶

This chapter describes the most commonly used stock management features provided by the OrderFlow system.

Goods In¶

In day-to-day warehouse operations, stock is added to the warehouse through the receipt of a delivery. A delivery is the arrival of physical goods at the warehouse door.

OrderFlow represents this operation as a ‘Delivery’ object, which may or may not have ‘Delivery Lines’ attached, depending upon whether the contents of the delivery are known in advance.

The contents of a delivery may be known in advance if OrderFlow is informed of an Advanced Shipping Note, or indeed if the delivery is in direct response to a Purchase Order. More details about these concepts can be found in the Warehouse Processes Guide.

If the contents of a delivery are not known, then the items in the delivery are scanned and quantities confirmed. OrderFlow then creates the delivery lines from the supplied information.

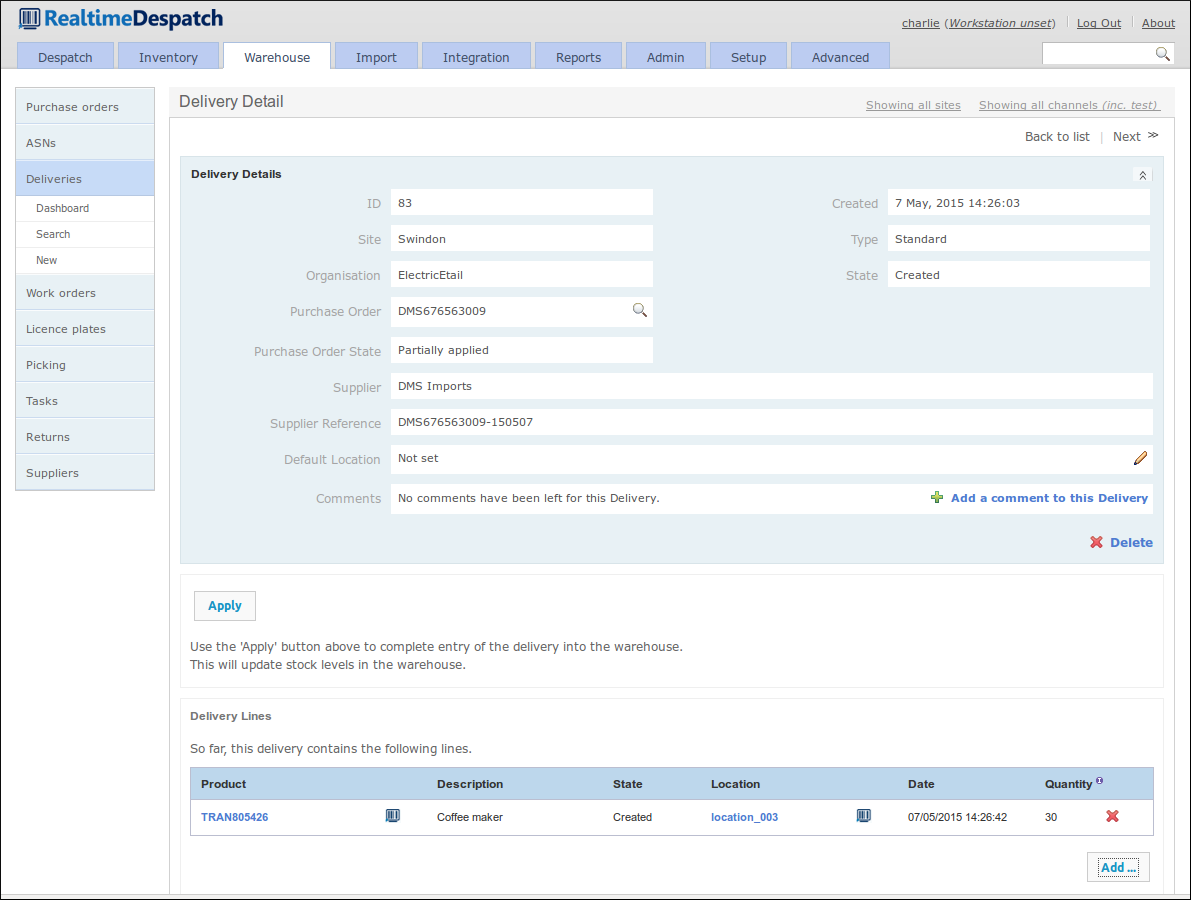

Once a delivery is applied (either incrementally or in one go), the stock in OrderFlow is credited. The delivery detail page (shown below) shows all delivery-related information.

The stock credited to OrderFlow can be handled in various different ways. The most simple is for it to be credited to an incoming location and then put away to pickable or storage locations. This is achieved via a stock move task, detailed in the following section.

More complex methods of processing delivered stock include routing straight to packing (cross-docking), to consolidation, or a combination of these (and more). More details on this can be found in the Warehouse Processes Guide.

Stock Move Tasks¶

At their most basic level, stock move tasks are simply instructions to warehouse operators to move one or more products from one or more source locations to one or more target locations.

They can be used for all sorts of processes - the simplest being putaway or replenishment processes, where stock is routed to or from storage locations (respectively). (Putaway processes can also route stock to pickable locations.)

Stock move tasks are also be used to drive the picking process - even dynamically when handheld devices are in use. Other common uses of stock move tasks include routing stock from storage to consolidation locations.

Storage, Replenishment and Reordering¶

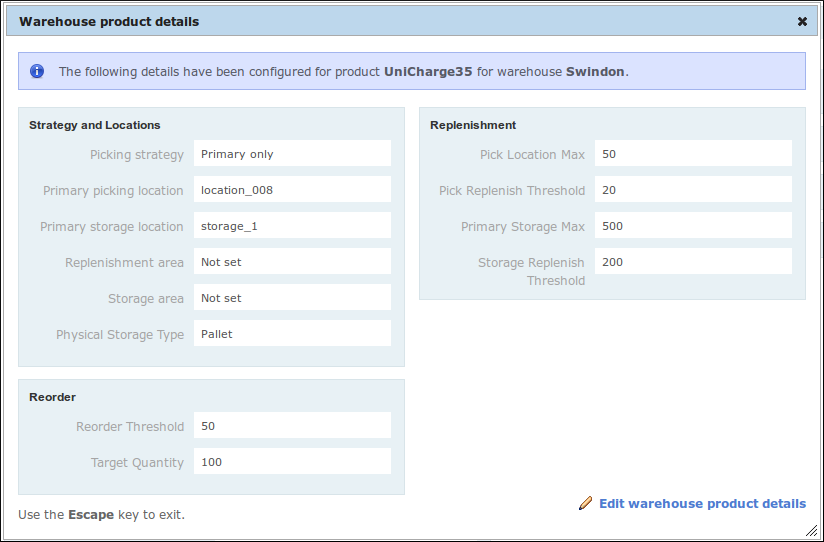

Products in OrderFlow can be configured to have specific attributes, that allow their movement and behaviour to be finely controlled. These setting can be applied per site, so different behaviour can be applied to different warehouses.

For example, a storage area or a more specific storage location can be defined for a product, which directs OrderFlow where to put away stock for this product.

Similarly, a primary picking location can be set, which restricts the typical picking processes to that location. In this case, replenishment of stock from storage location(s) to the primary picking location must occur before this product can be picked.

Also, a reorder threshold can be set for a product, which defines the minimum number of product units that are held in a warehouse before it is included in a reorder report. This will ultimately result in the product being included in a purchase order which, when imported into OrderFlow, will show the product as being ‘on order’.

The following screenshot shows the ‘Warehouse Product’ configuration details that can be applied:

Returns¶

When the recipient of an order returns a product (or products) for any reason, they usually send those products back to the warehouse from where they were despatched.

OrderFlow supports processes to allow these goods to be checked back into (typically) a quarantine location, ready for whatever reconditioning or repair needs to take place before returning to stock. Sometimes the goods have to be sent back to the original supplier, so will not be returned to the normal storage / pickable stock for re-use.

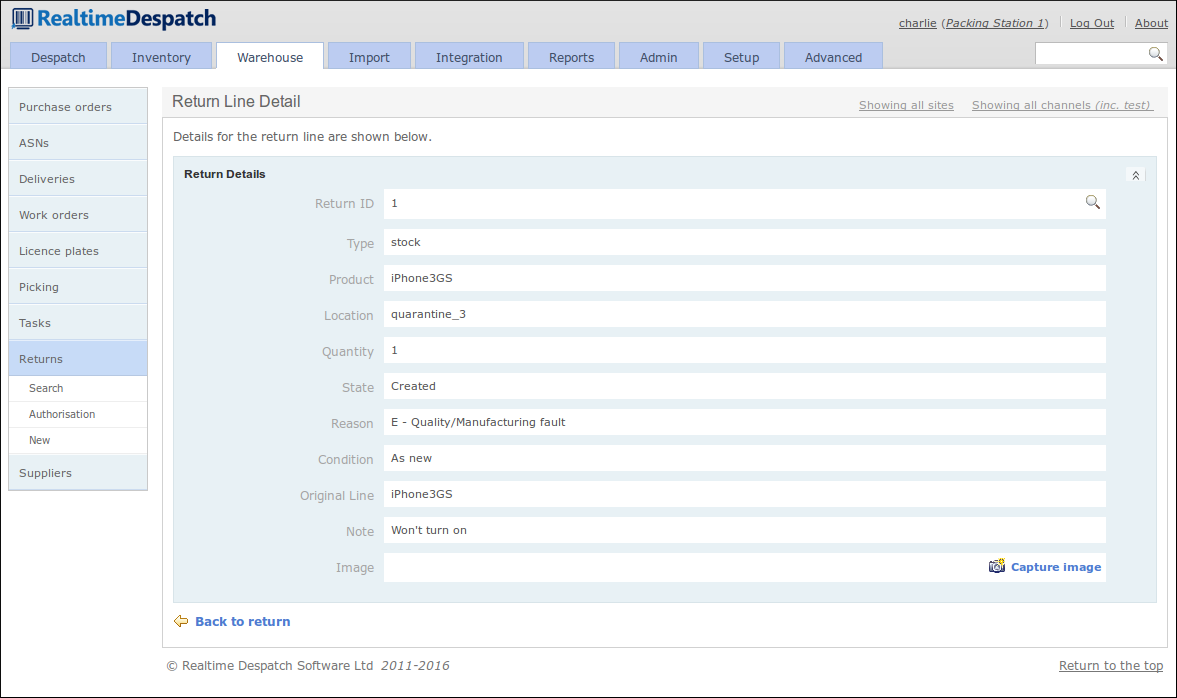

This ‘returns’ process allows the user to record the condition of the returned goods, the customer’s reason(s) for returning the goods, and (possibly) whether they believe a refund should be paid. The following screen shot shows the detail of a return line: