Stock Management

Stock Management

Adding Stock

There are two ways that stock can be added into the warehouse on OrderFlow. An initial stock position can be imported or manually entered. Once a system is operational, stock is usually received into the warehouse through deliveries. The details for this are covered in the Goods In section of the Warehouse Operations chapter.

Stock Checking

Although OrderFlow keeps a tight control of the location of every unit of stock in a warehouse (or in several warehouses), it can happen that the real-world situation can fall out of step with OrderFlow's view of it. This is most likely to be because stock is physically moved without following direction from OrderFlow, or without reflecting that move in OrderFlow.

To re-align OrderFlow's picture of a warehouse's stock position, a stock check mechanism is required. This can be a one-off confirmation of the number of units of a specific product in a specific location. Or it could be assigning a specific use to a request to visit multiple locations and scan/confirm the number of units of each product found in those locations.

Handheld Stock Checking

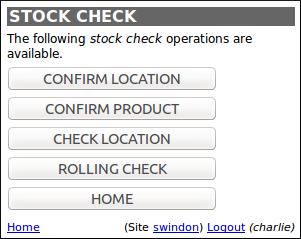

By its nature, stock checking is best performed on a handheld device, so OrderFlow provides most of its stock-checking functionality through its handheld interface:

The following sections detail each of these stock-checking functions.

Confirm Location

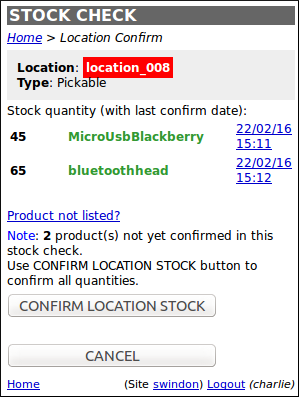

The Confirm Location handheld function allows a user to scan a location, after which they are presented with the stock position in that location:

The user can then choose to adjust any stock quantities as required, or confirm any unconfirmed quantities. The ability to add products that are physically present in the location, but OrderFlow thinks aren't, is available via the Product not listed? link.

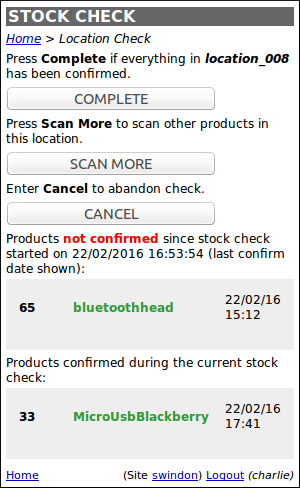

Once the user is confident that OrderFlow accurately reflects the stock in the select location, they can confirm this on the confirmation screen. This gives them the option to scan more products if necessary, or to confirm that the stock position presented is complete:

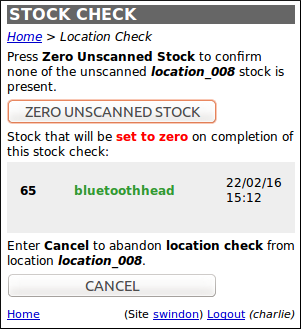

OrderFlow then requests a final confirmation that any stock that OrderFlow thought was in the location is definitely not in the location:

Once a location has been confirmed, the user can move onto the next location of their choosing. This is very much a user-directed stock checking operation, so there is not much scope to intelligently target specific locations. If this type of stock-checking is required then a rolling check would be required.

Confirm Product

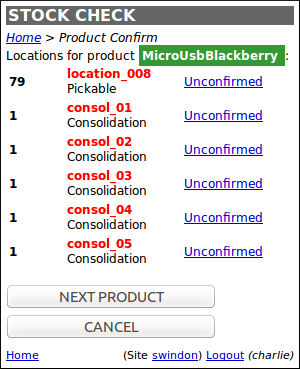

The Confirm Product handheld function allows a user to scan a product, after which they are presented with the stock position for that product in each of the locaitons where it is held:

Again, the user can then choose to adjust any stock quantities as required, or confirm any unconfirmed quantities.

Once the stock for a product has been confirmed, the user can move onto the next product of their choosing. This operation is a product-driven one, and again relies on the user deciding which product(s) to target.

Check Location

The Check Location handheld function allows a user to scan a location, after which they can scan products and confirm the quantities in that location.

This is effectively a 'blind' stock check, where a user blindly scans the product(s) and enters the quantity of each product, without any prior knowledge of what OrderFlow thinks is in the location.

Again, similarly to the Confirm Location operation, once a location has been checked, the user can move onto the next location of their choosing. The rolling check can be used if the user needs to be directed to specific locations.

Rolling Check

The Rolling Check handheld function is a stock-checking operation that is driven by OrderFlow, in that OrderFlow determines which locations need to be checked, and in which order.

The benefit of the rolling stock check is that, not only do the "oldest" locations get checked soonest, but also multiple users can perform rolling stock checks at the same time, in the same area.

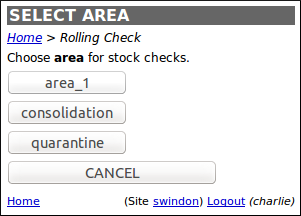

The user can select the area in which they would like to perform a rolling stock check:

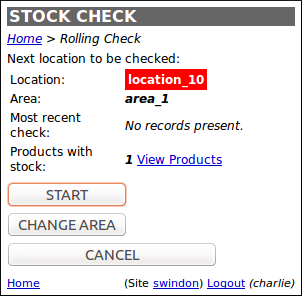

They will then be presented with the next location to be checked in the selected area. This location is derived from running the "Oldest stock check location" report.

This report uses the last_stock_check and location tables to return the location that has not been checked for the longest time (or has never been checked at all), in the selected area. If more than one location satisfies this condition, then the locations are ordered by sort indicator then reference.

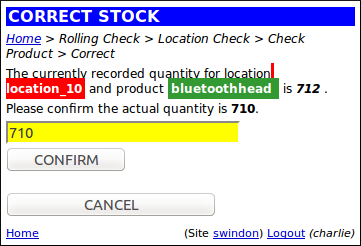

As with the other types of stock check, the user can then scan products and confirm quantities in the location. If the quantity entered differs from the value that OrderFlow currently holds for that product/location combination, the user is required to confirm this difference:

External Stock Checking

When a comprehensive stock check of the entire warehouse is required, such as an annual stock check, some organisations prefer to perform this "off-platform", i.e. without using OrderFlow. The reasons for this may be historical, in that the warehouse staff know exactly how to do it the way they have always done it. Or it may be because they don't have enough handheld devices for all the staff needed to complete the stock check in the time available.

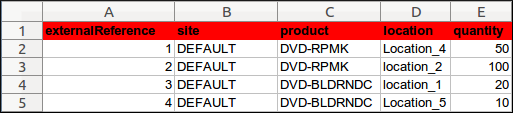

OrderFlow supports this activity by allowing the results of the off-platform stock check to be imported, using a product location import. This contains every product / location combination in the warehouse, alongside the quantity of stock for that combination, e.g.:

Once a product location spreadsheet is imported (using the merge operation), each new stock position is persisted, and any difference between the old and new positions is recorded as a stock change on OrderFlow, with a contextual note to make it clear that the change was as a result of an imported stock position.

Stock Move Tasks

OrderFlow features a generalised framework for managing stock moves within the warehouse. Stock Move Tasks can be set up for a variety of purposes.

An important application of this is in Replenishment, described below.

Replenishment

Replenishment is the term used to describe the process of moving stock from storage locations to pickable locations within a warehouse.

Storage locations will typically be locations that are less accessible than pickable locations, for example pallet racking that requires a fork-lift or an aerial work platform (or "man-up") to reach. Retrieving stock from these locations takes more time and can be more difficult. Additionally, specialist qualifications may be required to use the equipment to reach them.

Pickable locations, on the other hand, will typically be more easily accessible to picking staff.

The timing of when to replenish stock is influenced by several factors, including the capacity of the pickable locations, the 'box size' of the stock, the time it takes to access the replenishment locations, and most of all, the outstanding order line requirement.

OrderFlow supports 'priority' replenishment tasks and 'background' replenishment tasks.

Priority Replenishment will move whatever stock is required by existing shipments from bulk storage locations into picking locations. The scope of priority replenishment tasks is restricted to the items needed to by existing shipments with the state 'pending move'. It allows shipments that already exist within OrderFlow to be progressed

Background Replenishment is used to replenish the picking faces by moving stock out of bulk storage locations. An OrderFlow product definition can be given a 'Picking Threshold' value and a 'Picking Location Max' value. When the stock available in the picking face falls below the 'Picking Threshold' the backgroundtal quantity available in the pick face up to the value defined in 'Picking Location Max'.

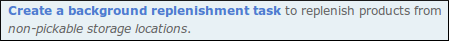

OrderFlow uses its task framework to drive the replenishment process. To manually create a 'background' replenishment task, navigate to Warehouse --> Tasks --> New and select the 'Default Background Replenishment' task type. There is a short-cut link to this page on the 'Background replenishment' dashboard fragment, which is present by default on the Tasks dashboard:

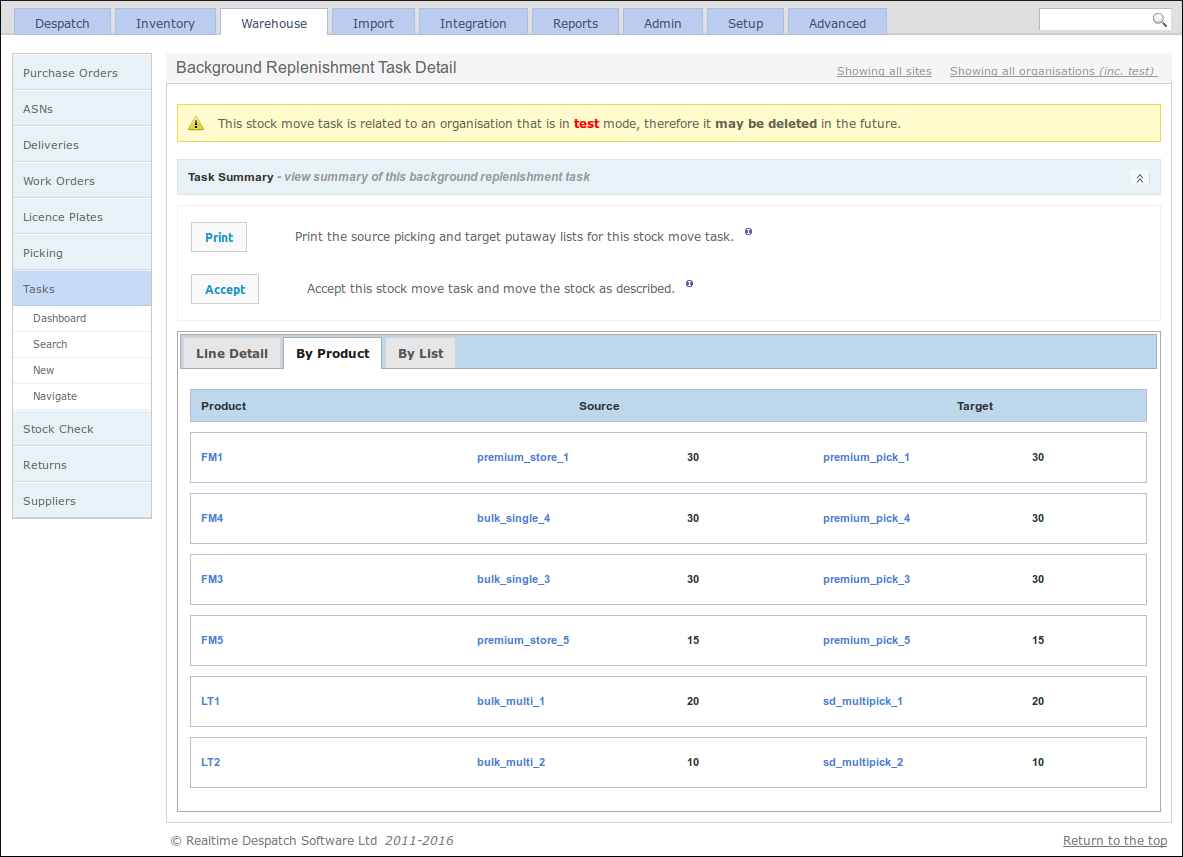

The following screenshot shows a background replenishment that was created in this way. Note the three tabs ('Line Detail' / 'By Product' / 'By List'), that show the constituents of the task from different perspectives.

The task definition that backs this task contains the configuration that dictates how OrderFlow creates the background replenishment task. In this case, the task uses the "Incremental Target-centric" strategy. This uses a "background picking replenishment strategy" report to populate a map of products to quantities of each product that requires replenishment. This map is then used to create the required stock move lines in the task, based on available stock in the warehouse.

The difference between background and priority replenishment tasks is encapsulated in the report that each task definition uses. The background replenishment uses "background picking replenishment strategy" report, the priority replenishment task uses the "priority location picking replenishment strategy" report.

Task configuration is a complex area - more details on this subject can be found in the Scripting Guide.

Task Completion

Task completion is the process of carrying out the stock moves identified by the task lines. It can be used for replenishment and other tasks.

OrderFlow supports two modes of completion for tasks: paper-driven and via a handheld terminal.

Desktop-based task completion is achieved through a combination of a paper picking and putaway report, as well as a set of user operations via the desktop user interface to accept the task, print the paperwork, and to record modifications after picking and putaway. It is useful in environments where handheld terminals are not enabled or supported.

The typical workflow used would be as follows:

- the task is created on the system, either manually or on a schedule. Once creation is complete and the task is ready for processing, the task state will move to ready.

- an operator accepts the task, moving the state from ready to accepted.

-

the operator will then print paperwork for the task. The printout will include:

-

a list of the source lines, which identify the source locations and products to be picked, in picking order.

-

a list of the corresponding target lines, identifying the putaway locations for the product.

-

the operator will then physically carry out the stock moves on the system as identified by the lines of the task. Any lines that cannot be completed, or quantity changes that need to be made, are recorded at this point on the paperwork. At this point, no changes have been reflected on the system.

- The user then applies the task. Prior to applying the task, the user can record any modifications from the originally suggested locations and quantities. At this point, the stock changes associated with the task are reflected on the system.

TODO - add screenshot

Handheld terminal-based task completion has the advantage that each move is verified using a physical scan.

TODO - add instructions and screenshot