Manufacturing

Manufacturing

Module Requirement

The functionality described in this section requires the modules rtd2-product-group and rtd2-warehouse-bom.

OrderFlow supports a manufacturing process. It does this via the following capabilities:

- It can hold definitions for raw materials.

- It can hold definitions for manufactured products.

- It holds the 'ingredients' of a manufactured product in a bill of materials, i.e. which raw materials in which quantities are required to manufacture that product.

- It provides a process that allows a user to 'check out' enough raw material stock to manufacture the required number of manufactured products.

- It provides a process that allows a user to 'check in' the number of units of the manufactured product (created from the raw materials).

The raw materials can be specified in units, by weight, or by volume.

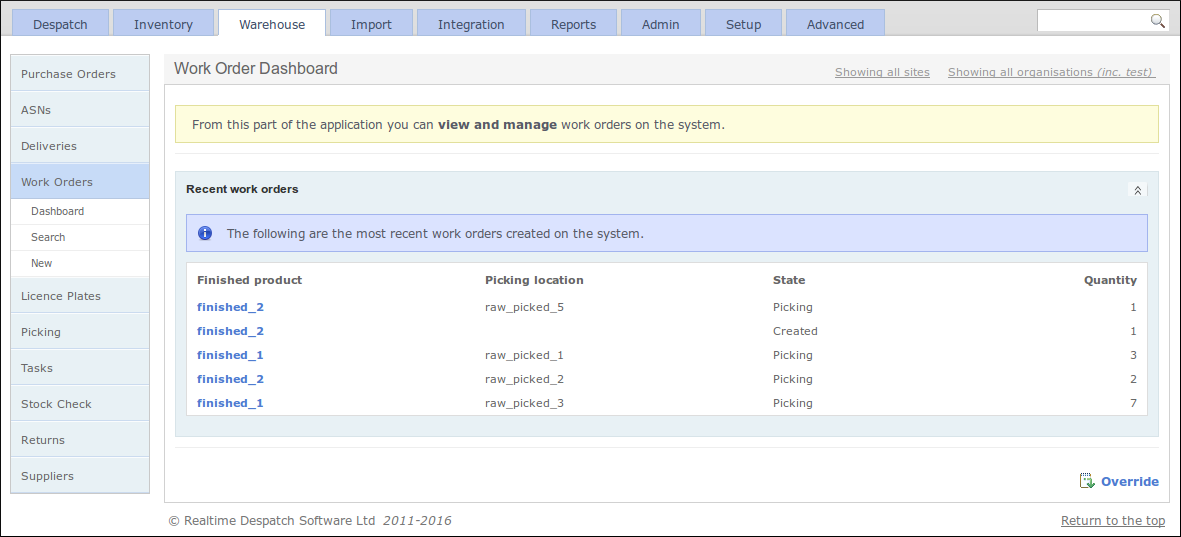

OrderFlow uses Work Order terminology to support its manufacturing process, in that the process of turning raw materials into finished products is managed using a Works Order entity. These can be seen under Warehouse --> Works Orders in the desktop interface:

Raw Materials

In OrderFlow, a raw material for a works order is simply a product of type raw_material. There isn't anything special about this product type, but it is not usually sellable and the stock levels are not usually sent to any upstream systems (i.e. shopping carts.).

Raw materials can be specified as units, as weights or as volumes, e.g.:

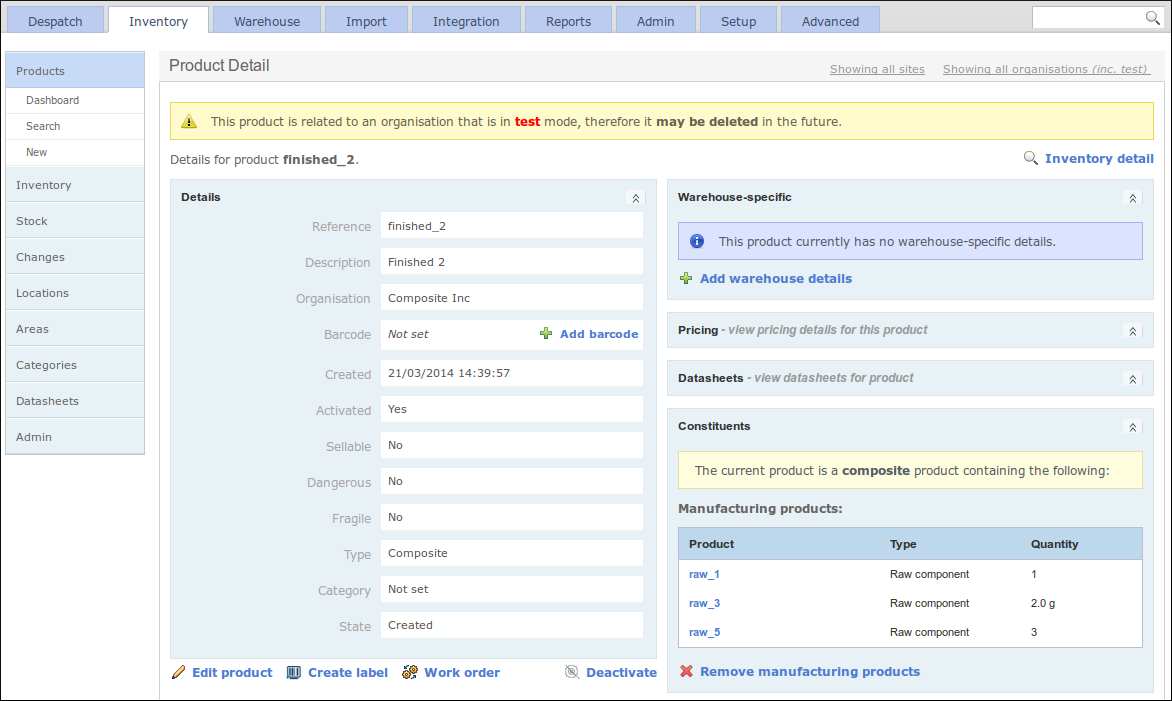

Finished Products

A finished product is defined as a product of a type that has the composite attribute, indicating that its definition depends on other products. These constituent products are likely to be defined as raw materials, but could also be packaging materials, or anything else that is required to create the finished product.

The following screenshot of a product detail page for a finished product shows the constituent products raw_1, raw_2 and raw_3:

Creating Product Relationships

In a customer's environment, the relationships between finished products and raw materials usually have to be carefully defined, there is no facility to create these relationships on an ad-hoc basis via the desktop interface.

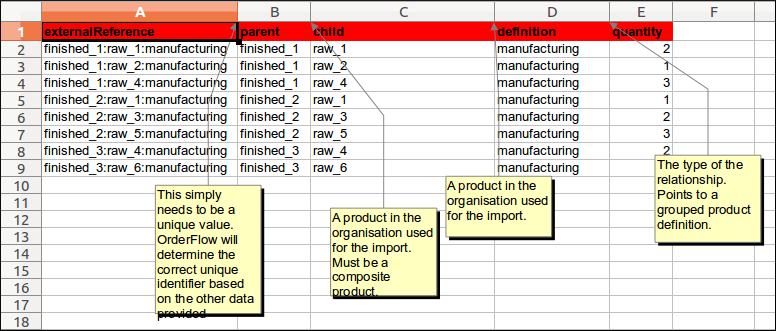

Instead, these relationships can be imported using a grouped product spreadsheet. This defines the quantities of raw materials required for composite products, in either units, or the default weight (or volume) storage units. (These are held in the Product weight storage unit and Product volume storage unit properties respectively.)

An example of a grouped product spreadsheet for manufacturing products is shown below:

The definition column refers to a Grouped Product Definition entity, which defines the type of grouped product relationship. For works orders, the grouped product definition to use to define relationships between raw materials and finished products is the Manufacturing definition.

Grouped Product definitions can be managed from the Advanced --> Warehouse --> Grouped Products menu in the desktop interface.

Works Order Creation

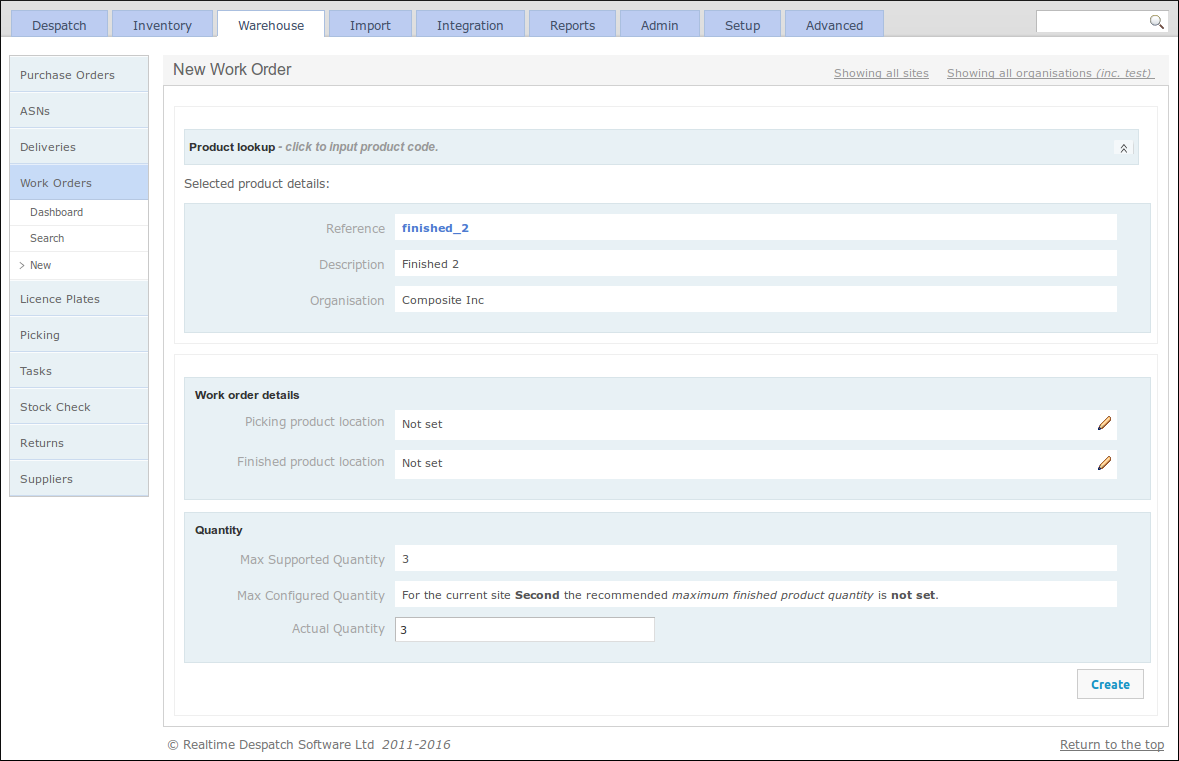

Once the relationships between raw materials and finished products are created (using grouped products), an actual Works Order can be created via the desktop interface, from the Warehouse --> Works Orders --> New menu. The user finds the finished product using its reference, after which OrderFlow uses the available raw material stock to calculate the possible number of units of the finished product that could be made. This value is displayed in the 'Max Supported Quantity' field:

The 'Max Configured Quantity' field holds any warehouse-specific limit to the number of units that can be manufactured in a single work order. This value can be configured in the finished product's warehouse product configuration.

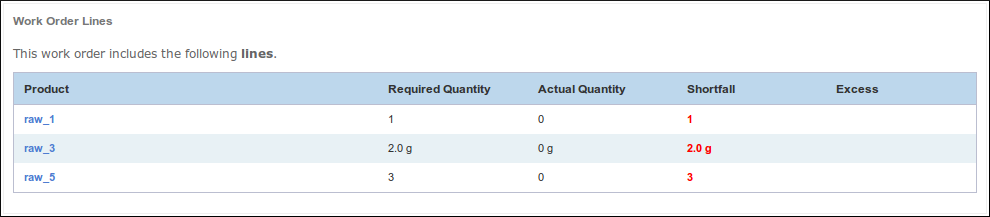

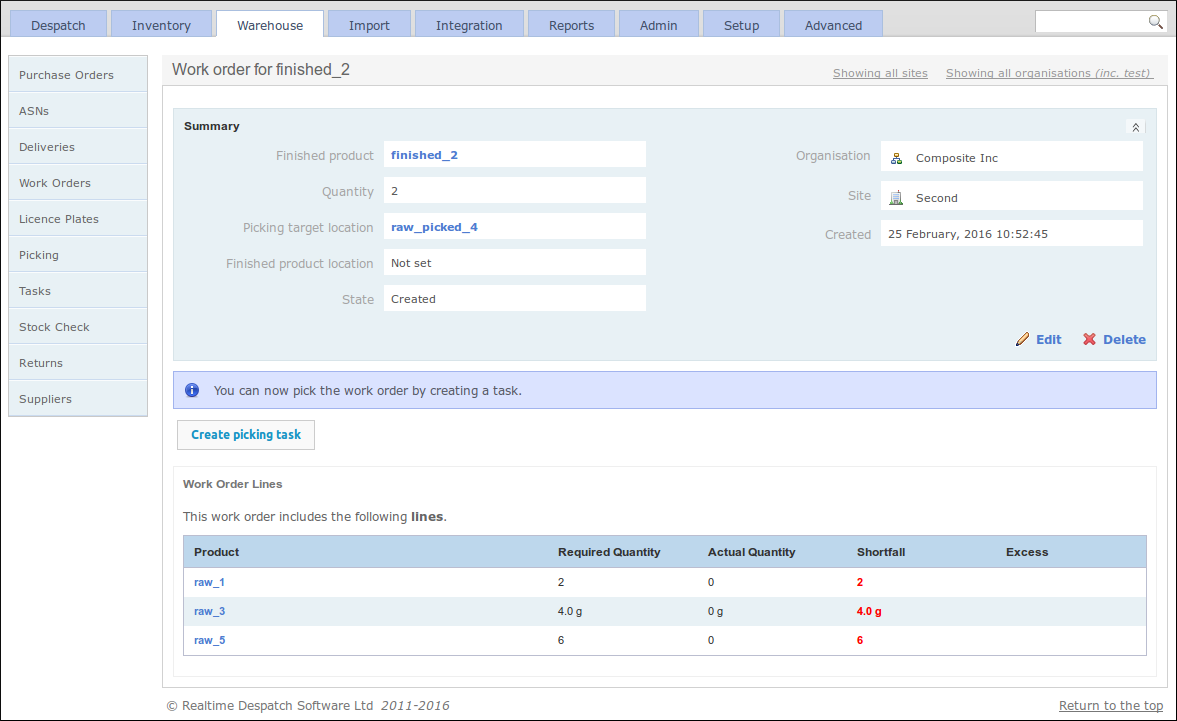

Based on these maximums, the user can then decide how many units of the finished product to manufacture, then select the 'Create' button. The resulting work order contains work order lines, which detail the quantities of raw materials required to make the number of finished products requested by the user:

Works Order Picking

Once the picking target location is set, a task can be created for the work order. The purpose of such a task is to direct a warehouse user to physically pick the stock required for the manufacturing process, into the picking target location. (The task definition used is hard-coded to pick_for_manufacturing.)

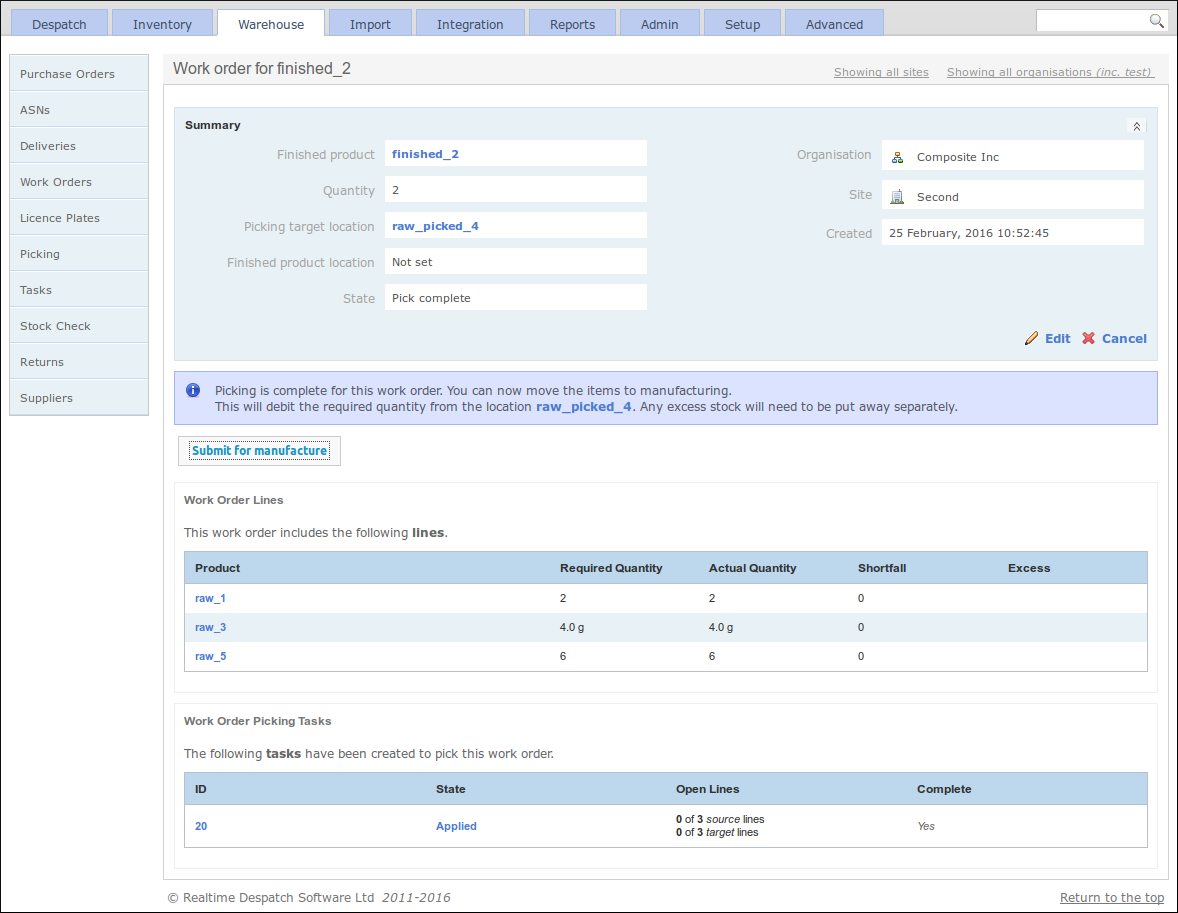

Once the task is applied, i.e. the stock has been picked, the works order can be submitted to manufacturing, as shown in the following screenshot:

Works Order Completion

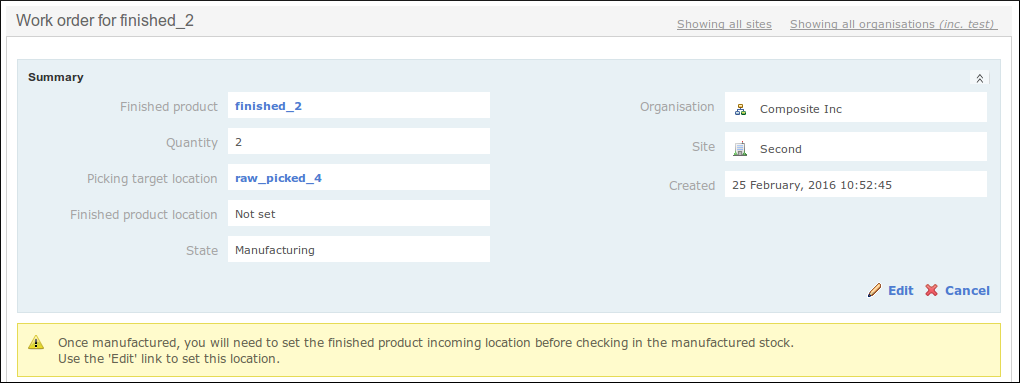

If the finished product location is not set, the works order detail page advises the user to set this, otherwise the manufactured stock cannot be checked back into OrderFlow:

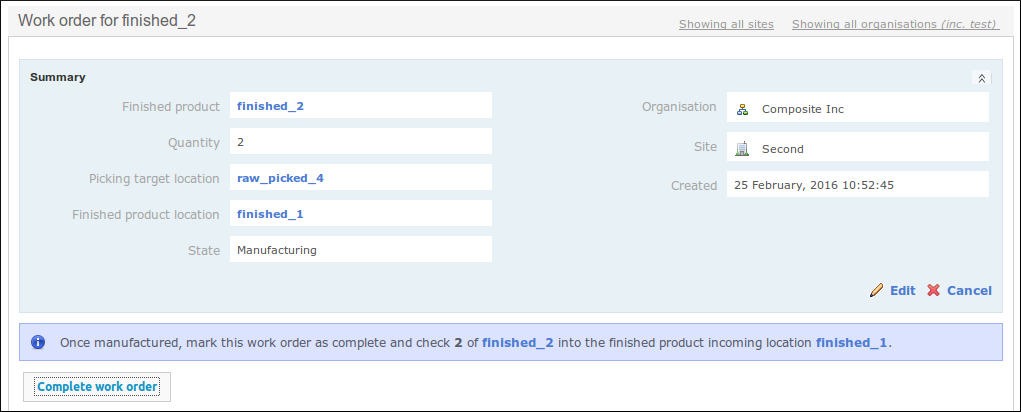

Once set, the works order can be completed:

When the work order is completed, OrderFlow credits the finished product

location with the requested number of units of the finished product. This

stock can then be moved to pickable locations (or picked directly if the

finished product location is pickable), so that it can be picked for outgoing

shipments.

The entities created in OrderFlow during the manufacturing process include a Work Order entity, attached to which will be one or more Work Order Line entities. A Work Order Task entity is created to manage the relationship between the works order and the underlying pick-for-manufacturing Stock Move Task.