Picking

Picking

Picking describes the processes by which stock is retrieved from locations in the warehouse to be made available for despatch, typically via a Packing process.

Once it has been established that there is sufficient stock in the warehouse to fulfil the orders, and that specific order lines have been assigned stock from specific pickable locations, it is possible for warehouse staff to actually pick the stock from those locations.

As detailed in the "Shipment Picking" section in the Introduction to OrderFlow document, OrderFlow provides many options for physically picking stock. These options can be broadly categorised into paper-based picking and handheld-driven picking.

Most picking is controlled by the configured Shipment Batch Types, which can be found under the Setup --> Batch Types menu on the desktop interface.

Batch Selection

Module Requirement

The functionality described in this section requires the module rtd2-batch.

The pick and pack process followed by a shipment is determined by the "Batch type" it is associated with. "Batch type" definitions can be used to define the optimal despatch process followed by different types of shipment:

- single-line shipments might be picked using a paper based picking process that

allows the picker to make one sweep around the pciking face and present the packer with a mixed tote of barcoded items - multi-line shipments might be picked into a sub-divided cart, the handheld can prompt the picker to put the required number of each item into the correct subdivisions, making it easy for the packer to find the items required for each shipment when packing.

- multi-line orders that need to be picked from more than one area of the warehouse might be picked in a handheld process that requires the items to be moved into a consolidation location.

Shipments are associated with the appropriate batch type by the application property 'batch.selection.script'. The batch selection script is used to automatically assign shipments to the appropriate batch type and then put into a specific batch with other shipments that have the same profile.

Paper-based Picking

A paper-based picking approach requires the product / location quantities for all order lines to be picked to be printed out and given to a warehouse user to perform the pick.

It is usual for the shipments (that contain the order lines to be picked) to be grouped together in batches, as it would be inefficient to print one shipment at a time, go and pick it, then pack it and repeat for the next shipment. The number of shipments grouped together (the "batch size") depends upon the 'profile' of the shipments, i.e. how many order lines and the typical quantities of those lines. It can also depend on the products themselves - for example small products such as batteries can be picked in greater numbers than larger products such as storage boxes.

The most useful delineation is between single-line and multi-line shipments. Single-line shipments can usually be picked into a single picking cart, whereas multi-line shipments have to be picked into sub-divided picking carts, or picking trays or similar. This distinction is driven by how the picked items will be handled at the packing desk, in that when a product is picked out of the cart, a single-line shipment will only ever require more units of the same product to be picked out of the cart. A multi-line shipment will require the packer to pick additional (different) products out of the cart - products which may be buried under other products in a single cart. If the products for a multi-line shipment are all picked into the same sub-division of a sub-divided picking cart, it will be easy for the packer to find all the products for the shipment.

Built-in picking reports available include:

-

Picking List (A4) - the default picking list, that details the quantity of each product to pick from each location. This is ordered by the batch type's Report Picking Sort value, which will typically take into account the location in some way, to ensure an efficient route through the warehouse. Note that shipments are not separated in any way in this report, so if two shipments require the same product to be picked, then there will be a single line on the report with the combined quantity.

-

Barcoded Picking List (A4) - similar to the default picking list, but with product barcodes displayed for each line.

-

Picking List with Full Description (A4) - similar to the default picking list, but with full product description displayed for each line.

-

Single-line Picking List (A4) - similar to the default picking list, but each product / location combination is broken down into the quantities required for each shipment.

-

Indexed Multi-line List (A4) - similar to the single-line picking list, i.e. each product / location combination is broken down into the quantities required for each shipment. Additionally, each product / location / shipment combination is assigned an index, which can be used to direct the picked stock to a specific sub-division of the picking cart. The index will be the same for different lines in the same shipment.

-

Multi-line List (A4) - similar to the default picking list, but this report groups the product / location quantities by shipment, so that all lines for a single shipment are displayed alongside each other. This list relies on Order Line Locations being created for the shipments concerned, so it makes no sense for this report to be run before all shipments are pickable.

-

Multi-line Picking Note (A4) - similar to the multi-line list, but each shipment is printed on a separate page.

-

Barcoded Multi-line Picking Note (A4) - similar to the multi-line note, but with product barcodes displayed for each line.

Once printed, a picker can follow the picking list to pick the required items into a cart of their choice. During this process, OrderFlow does not know the exact location of each of the stock items, so it assumes that the stock is still in the source location until the user informs it otherwise.

Depending upon the batch type configuration, the result of the pick operation can be stock in the picking cart, associated with lines and shipments in the following states:

Handheld-based Picking

Module Requirement

The functionality described in this section requires the modules rtd2-batch, rtd2-batch-taskpick and rtd2-handheld.

The alternative to paper-based picking is for the warehouse users to be directed through the picking process by using a handheld device. OrderFlow can be configured to direct picking operations via its Handheld interface.

Handheld-based picking can be used to pick stock for shipments in batches, but it can also be used to pick stock in other processes, such as picking from storage locations into picking or consolidation locations.

Handheld Batch Picking

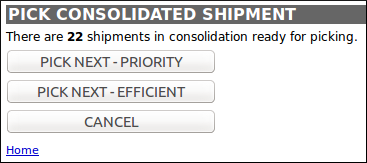

Shipments can be routed to handheld-based picking by being assigned to shipment batches of a type that has a picking type of handheld. Batches of this type (in the handheld_pickable state) will be visible on the PICK --> PICK BATCH menu on the handheld interface, e.g.:

These batches are ordered by the sort indicator of the batch type, then the batch id. This allows batches of certain types to be prioritised over others.

When one of the available batches is selected, the user scans the picking cart that they are using, then confirms that they want to proceed with creating a 'handheld_picking' Stock Move Task to drive the batch pick. The first open line (by id) of that stock move task is then presented to the user:

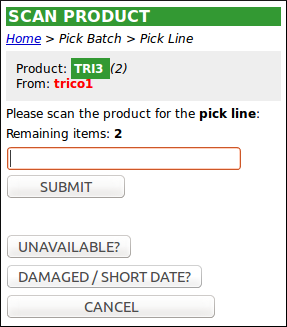

For each line, the user then scans the recommended source location (i.e. the pickable location where the stock is currently residing), then the product(s) from that location:

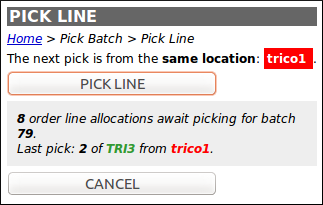

Once picked, the user is directed to pick the next line (which could actually be from the same picking location):

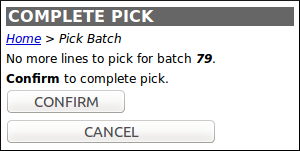

Once all the stock move task lines (which equate to Order Line Location entries) have been picked, the user can then confirm that they have completed the batch pick:

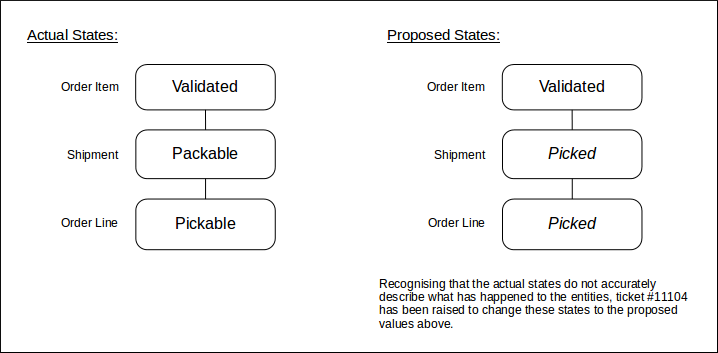

The result of a handheld batch pick will be stock in the picking cart, associated with lines and shipments in the following states:

The picked stock can be destined for one of two purposes, defined by the picking target of the batch type. If this is set to Packing then the picked stock can be taken to a packing station, to be physically packed into the required packaging (see the Packing section). This is the normal case, especially for single line shipments.

If the batch type's picking target is set to be Consolidation then the picked stock is destined for the shipment consolidation area. Once a full batch pick has taken place, a separate task will be initiated to move the items to the individual locations in the consolidation area (see the Consolidation section below). This is typical for large batches of multi-line shipments.

Handheld Picking by Sequence

Module Requirement

The functionality described in this section requires the modules rtd2-order-consolidation and rtd2-order-pick

OrderFlow support another mechanism to pick stock; that is by using its concept of picking sequences.

This section will be expanded upon in a future version.

Consolidation

As described in the Introduction to OrderFlow document, consolidation in OrderFlow refers to the process of the temporary storage of some of the stock for a multi-line shipment, usually in the absence of all of the stock.

A shipment that is assigned a consolidation location is considered to be "in consolidation", regardless of whether yet there is any stock in that location. If a shipment is in consolidation, its consolidation location can be seen on the shipment detail screen:

Picking To Consolidation

Stock can be routed to consolidation locations via the following mechanisms:

- From Delivery - some organisations order stock from their suppliers only after they have received orders (called just-in-time fulfilment). Such stock will be received in deliveries, some of which will be destined for shipments in consolidation. The Warehouse Consolidation section covers this process in more detail.

- From Storage locations - some consolidating multi-line shipments can have lines that can be fulfilled from stock that is stored in non-pickable storage locations in the warehouse. Moving such stock will be driven by the creation of a Pick batch to consolidation stock move task.

- From Pickable locations - similar to from storage locations, but where the source location is pickable.

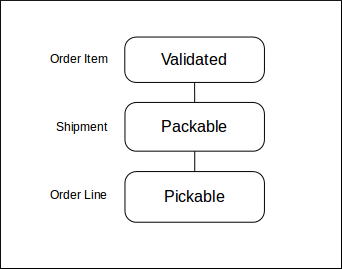

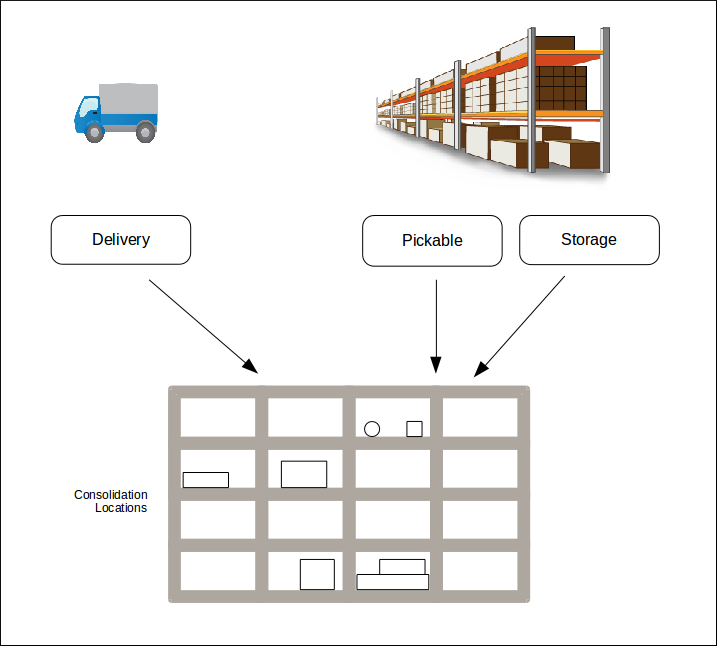

These mechanisms are loosely depicted in the following diagram:

Picking From Consolidation

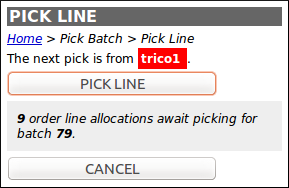

Once all the stock for a shipment is present in its consolidation location, it can be picked from consolidation to take to a packing desk. OrderFlow supports this process using its handheld interface to direct a user to the next completed shipment's consolidation location, so that they can then scan the products into a picking cart. The picking cart can then be taken to a packer.

The following application properties are used to sort the completed shipments into priority or efficient picking order (respectively):

- shipment.consolidation.priority.sort.expression

- shipment.consolidation.efficiency.sort.expression

This process is accessible from the PICK --> FROM CONSOLIDATION menu on the handheld interface: