Areas and Locations

Areas and Locations

Stock in a Warehouse Management System is represented by Products present in Locations. Locations themselves are found in Areas which are in turn contained in Sites. The warehouse as a whole is typically represented as a site, although it is possible to have multple 'logical' sites represented within a single physical warehouse premises.

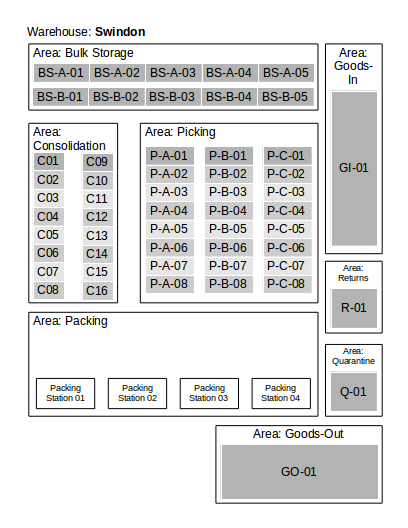

An example warehouse layout is shown below:

In order to understand how stock management works in OrderFlow, it is important to understand how products and locations can be organised, controlled and configured on the system.

Entities

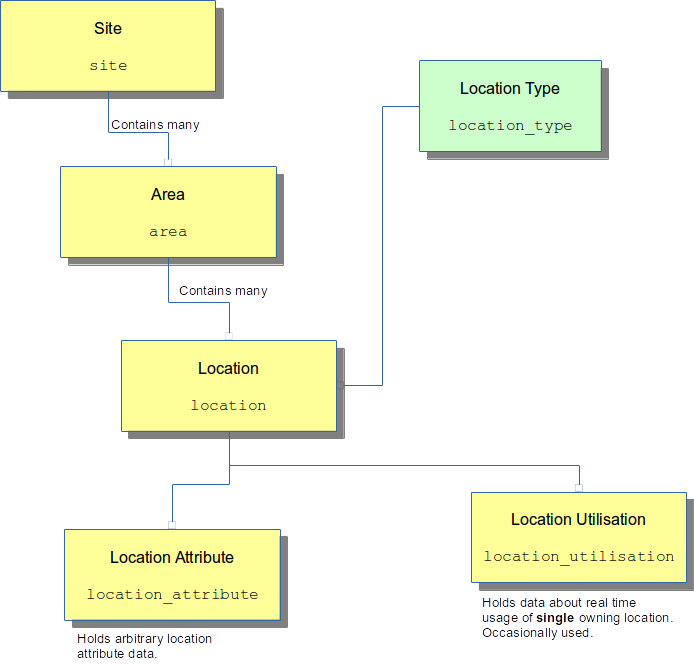

The diagram below shows the relationships between the entities associated with OrderFlow areas and locations.

These are discussed in more detail below.

Areas

An OrderFlow Site can be subdivided into different physical areas. Every location on the system is tied to an area entry, which itself is contained within a site.

Areas should represent the physical layout of the warehouse rather than the ways in which different areas of the warehouse are used (e.g. each aisle of pallet racking and each different picking face might be defned as an area).

Areas are primarily a convenience that can be used in the user interface to help users find locations and which allow reports to be run for specific areas within a warehouse.

However, areas can be used to restrict putaway locations for individual products. Areas can also be used to define zones for picking operations, allowing for individual users to be limited to picking within specific areas.

Additionally, areas can play an important role in stock checking functions, as stock check activities are often segmented by area.

The areas are generally a mix of functional and physical.

Functional Areas

Functional areas are areas used predominantly for a specific type of operation, such as in the table below.

| Area | Usage |

|---|---|

| Goods In | An area near the shutter door where deliveries are first held before being processed and putaway. This is often an open floor space but may be marked out into sections |

| Returns | An area dedicated to the processing on returned items |

| Damaged | An area dedicated to holding damaged or stock that is unsaleable for any other reason |

| Consolidation | An area in which locations are temporarily associated with customer orders until all the required items have been brought together and are ready to be packed |

Physical Areas

Physical areas are areas which simply represent the physical space in the warehouse, as in the example below.

| Area | Usage |

|---|---|

| Mezzanine | A mezzanine floor |

| Aisles 001 to 050 | Defining each warehouse aisle as an area |

It is not necessary to define multiple areas within OrderFlow. Each individual location can be defined with specific attributed that will determine how it can be used. As a result it is possible to define 'goods-in' locations, 'freeze' locations and returns locations within a single area which encompasses the whole warehouse.

The only way in which areas are used within the system logic of OrderFlow is to provide default values for all the locations found within the area. If an individual location does not have a logical type it will inherit the logical type defined for the area.

However, in practice warehouse areas are very useful in helping users find their way around the warehouse and in breaking it down into subsections for reporting and for warehouse operations like picking and stock checking.

Locations

Locations are found within areas. Locations themselves are classified by logical location type. It is through the different characteristics of these location types that much of the location-related behaviour on the system is implemented.

Areas can also be used to define zones for picking operations,

Locations are one of the key entities in OrderFlow. All stock on the system is held within locations. Locations are the subject of most of the major warehousing and fulfilment operations from checking in of incoming stock, through to picking of order lines for fulfilment.

Locations included both static locations which occupy a fixed position within the warehouse, and mobile locations, typically used in conjuction with handheld terminals for picking and stock move operations.

OrderFlow stores a range of different data for a location:

- the logical type of the location, described in more detail in the Location Types section.

- the physical type of the location. Example values for this field might be 'bin', 'shelf', 'pallet', 'cart' or 'tote'.

- dimensions of the location, including length, breadth, height, area and volume

- for fixed position locations found within aisles, the elements of the location in terms of aisle number, bay, level can be recorded. In addition, if the position of the location on the left or right hand side of the aisle can be held.

- also for fixed position locations, both a sort indicator and a convenience indicator can be used to influence the system's selection of optimal locations for putaway and picking operations.

Allowing OrderFlow to hold detailed data on the elements of a location's position reduces reliance on location naming conventions to describe the position of locations. However, a suitable naming convention for locations is still recommended as it allow for much easier familiarity with the layout of the warehouse.

Location Utilisation

The location definitions described in the previous section tend to be static in nature; they do not change very often, and tend to change as a result of physical reorganisation rather than warehouse operations.

OrderFlow also allows for the capturing of more dynamic data on the use of location usage through the location utilisation table.

This table allows for data such as the following to be recorded:

- the number of products currently present in the location

- the total volume used, and the percentage utilisation of the location by volume

- a record of when the last stock check was completed

- a mechanism to 'lock' locations to (temporarily) prevent their use in certain processes

Locations are defined to be of specific Location Types.

Location Types

OrderFlow categorises locations into different types, to help it manage the flow of stock more easily. Location Types are configurable entities that can have any combination of various defined attributes. This allows for fine-grained control of how locations are used, particular to the specific customer needs.

There are many attributes of a location type - some commonly-used ones are detailed here:

- pickable: Determines whether this location can be used as a source location for picking operations. If stock is only in non-pickable locations, then replenishment of picking locations must occur before picking can proceed.

- storage: Indicates that the location can be used for storage. Only storage locations will typically be considered as target locations for putaway operations.

- multiProduct: Indicates that a location is designed to contain multiple products.

- incoming: Used specifically for locations for receiving incoming deliveries.

- damaged: Used to hold stock that is considered to be damaged.

- mobile: Used for locations which do not have a fixed physical position in the warehouse. Physically, may be a cart, cage, trolley, tote or some other mobile container. Used extensively in handheld scanner-based operations.