Goods In

Goods-In

The 'Goods-in' operation involves a Delivery of stock into the warehouse.

Deliveries are usually planned and expected. An organisation will place a Purchase Order with a supplier, detailing exactly what items and quantities are required. Supplier purchase orders can be imported into OrderFlow and used to check-in the associated delivery.

If no purchase order has been imported into OrderFlow, it is still possible to describe the contents of a delivery before it is received by using an Advanced Shipping Notification (ASN). An ASN can be used to specify what is thought to be in a delivery before it arrives.

The difference between a purchase order and an advanced shipping note within OrderFlow is that a supplier purchase order can be associated with multiple deliveries while an advanced shipping note is always used to describe a single delivery.

The OrderFlow Goods-In process will reconcile the details of what received with the associated purchase order or ASN and produce a discrepancy report where there are differences between what was expected and what was received.

It is also possible to create a delivery on OrderFlow 'on spec', without it be related to either a purchase order or an advanced shipping note. Where this is done no discrepancy report can be produced.

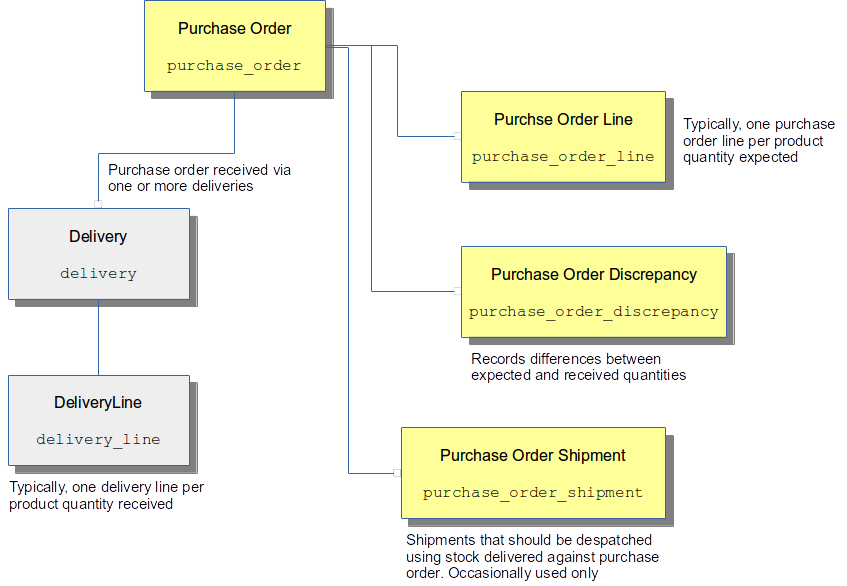

Purchase Orders

A Purchase Order can be of the following types:

- Supplier - placed against one of the organisation's suppliers.

- Bulk Transfer - transfer of stock from another warehouse, within the same organisation.

A Purchase Order Line holds an expected quantity against a referenced product, plus the outstanding quantity of units not yet delivered. It can additionally hold an external reference, typically supplied by an external system.

The following diagram shows the relationship between these entities.

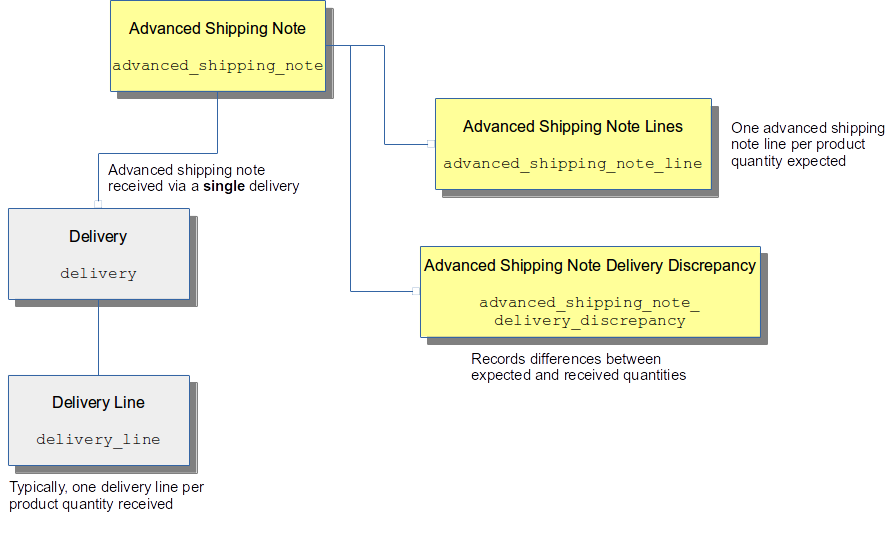

Advanced Shipping Notes

An Advanced Shipping Note can be of the following types:

- Stock - all items in the ASN must be stock items, i.e. when delivered they will be put away into stock locations.

- Container-to-stock - items are delivered against the ASN in containers, whose contents are not confirmed, so will need to be scanned before being put away into stock locations.

- Order - all items in this ASN are intended to be matched with pending orders as part of the Goods-In process, the incoming items will be packed and despatched rather than being put away into stock locations.

- Unrestricted - the delivery for this type of ASN is not restricted to any particular type.

An Advanced Shipping Note Line holds a quantity against a referenced product, and may also hold a (container) location reference or an order reference, depending upon the ASN type.

The following diagram shows the relationship between these entities.

Deliveries

In OrderFlow, a delivery can be one of the following 'standard' types:

- Stock (with deferred save) - the default delivery type, where all products and quantities have to be supplied (to create delivery lines) and the delivery applied before stock is credited to the warehouse.

- Stock (with incremental save) - similar to deferred save, but stock can be credited to the warehouse during the check-in process, instead of waiting until all product/quantity combinations have been supplied.

- Quarantine - similar to deferred save, but stock must be credited to a quarantine location; that is, a location whose logical type has the 'quarantine' flag set. This will credit the stock into the warehouse but will not increase the 'available' stock figure for the items received.

- Container to stock - stock is initially credited as 'unconfirmed', then a verification process must be followed before the delivery can be applied.

- From licence plates - creates one or more temporary licence plate locations that can then be used to route the incoming stock into several different warehouse workflows, typically via the handheld user interface.

Or it can be one of the following 'cross-dock' types. ('Cross-docking' is the process of using delivered stock to fulfil orders directly, without putting that stock away to warehouse storage locations and then subsequently picking it.)

- ASN cross-dock - stock is immediately cross-docked from a delivery that was created from an Order-typed Advanced Shipping Note.

- Purchase Order cross-dock - stock is immediately cross-docked to a shipment that has been associated with the same supplier purchase order that the delivery has been associated with.

- Licence Plate Purchase Order cross-dock - similar to the Purchase Order cross-dock type, but uses a licence plate mechanism to process the stock.

- Out-of-stock cross-dock - incoming stock is immediately cross-docked

with existing customer shipments that have the state 'out of stock'. The

delivery does not need to be backed by an ASN or a purchase order.

Instead, 'out of stock' that are out of stock are automatically matched to use the delivered stock most effectively. Incoming stock that is matched with single line shipments can be packed immediately, incoming stock that is matched with multi-line orders will be moved to a consolidation location.

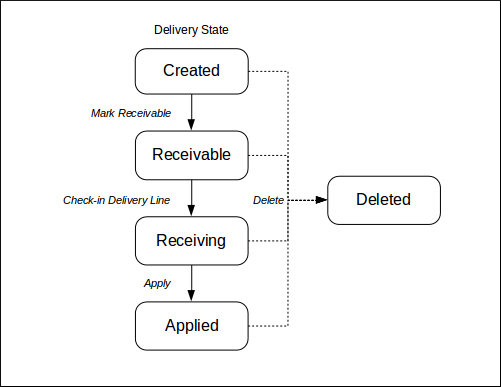

A Delivery has a lifecycle, defined by the following state transition:

Delivery Line entities will ultimately be created and attached to the Delivery entity, but exactly when these are created depends on the Delivery type (as described above).

A Delivery Line holds the received quantity against a referenced product, and also references the location in which the stock will be credited. Instead of a 'type', a delivery line has a variation, that determines how it will be processed. Delivery Line 'variations' are set by choices made during delivery creation, and can take the following values:

- Just-in-time (JIT) - the delivered units will either be cross-docked, or

routed to a consolidation location, in order to fulfil an order whose stock

has been ordered from a supplier just-in-time (rather than already held in

the warehouse). - Damaged - the delivered units will be routed to a location reserved to hold damaged goods.

- Bulk - the delivered units will be routed to bulk storage locations, using a licence plate mechanism.

- Incoming to stock - the delivered units will be put away to stock, after first being credited to an incoming location; that is, a location whose logical type has the 'incoming' flag set.

- Direct to stock - the delivered units will be put away to stock directly, i.e. without first being credited to any other location.