Picking

Picking

Picking Mode

The picking mode for a shipment is used to determine the workflow used picking and processing a shipment.

The main picking modes are batch, individual, task, consolidation_single and consolidation_multi.

Batch

This the most common picking mode used. Shipments are picked in groups or batches (also called waves). Before being grouped into a specific batch, the shipment needs to be associated with a batch type, which is typically done at import time with the help of a batch selection script.

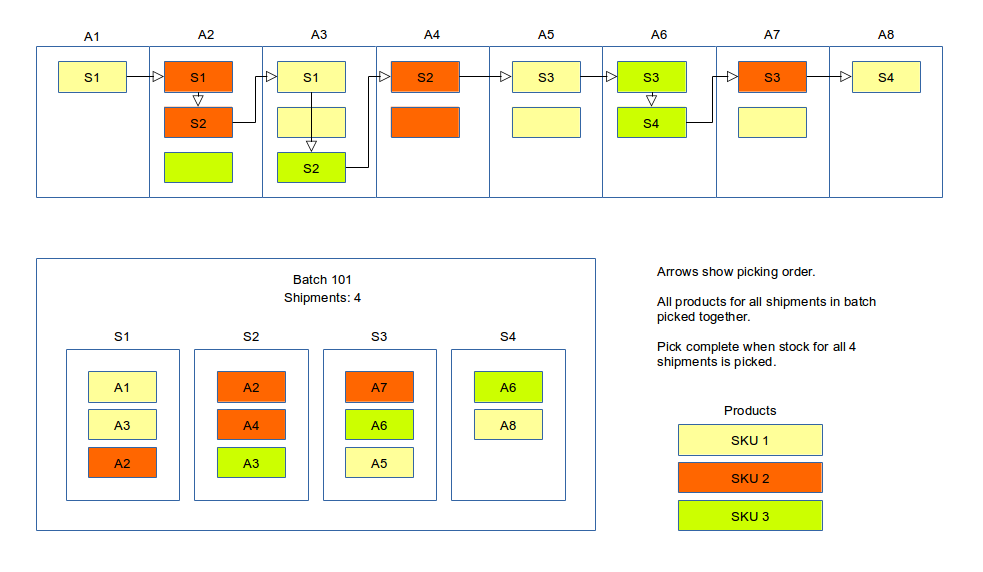

Once the shipment has been associated with a batch type and becomes pickable, it is eligible to be included in a specific batch. All of the shipments in that batch are picked together.

Individual

Shipments in this mode are picked individually as soon as they are eligible for picking. As the name suggests, they are picked one at a time, rather than in a group.

Task

Task-based picking involves a three stage process for which the initial picking stage is extremely efficient in terms of metres walked per pick. However it does involve a slightly more complicated process particularly for multi-line shipments:

- picking tasks for shipments are created once the shipment becomes pickable.

- pickers pick shipments efficiently by location across multiple tasks, into pick trolleys.

- the contents of the pick trolleys are emptied into shipment-specific consolidation locations.

- a separate picking process is then followed for picking shipments in consolidation once all of items required for the shipment are present in the consolidation location.

Consolidation single

This type of picking applies specifically for shipments in consolidation. Each shipment is picked to a single consolidation location. This allows for all of the items for the shipment, and only items for that shipment, to be present in the tote presented to the packer.

Consolidation multi

This type of picking applies also for shipments in consolidation, but allows for multiple shipments to be added to the same picking tote. The packer will receive a tote containing items potentially for several shipments.

Batch Picking

A Picking Batch is a grouping of shipments that are picked together. Organising shipments into batches can fulfil a number of purposes.

- related shipments can be grouped together to support a simpler or more efficient operation. For example, single line shipments can be picked more efficiently that multiline shipments, so it makes sense to pick them together. Also, it often makes sense to pick together shipments that share the same priority or courier.

- for paper-based picking processes, a consolidated picking list can be printed for all of the shipments in the batch. It also makes sense in some cases to also pick all of the customer paperwork (despatch notes or invoices) as part of a batch print operation. This can greatly save on time that would otherwise be required for per-shipment print jobs. It also allows for the use of high end printers, as well as for the preparation of paperwork in bulk as part of a background task.

- batches can also be used to support particular workflow processes. The obvious example is picking, either with the help of paper reports or handheld terminals. In some cases, other batch operations can be supported, such as marking all shipments in a batch as packed or despatched.

The diagram below shows a visual example of batch picking. Note that all of the shipments in the batch are picked in full during the batch pick. The ordering of the picking lines is such that the picking is as efficient as it can be subject to this constraint.

Batching Strategies

Batching allows shipments to be picked depending upon various factors and are usually customer specific.

Some examples are listed below:

- Priority despatch for express orders

- Courier collection times

- Optimising picking based on product location in the warehouse i.e. grouping single-line shipments for products in a defined area. It is more efficient for a picker to go once to an area to pick 12 items than to pick 8 item and return to pick another 4 items.

- Picking shipments in large warehouse i.e. keeping a picker in the same general area.

- If there is a mezzanine, for example, to pick products on the ground floor in one batch and pick products on the mezzanine floor in another batch.

- Split out products that are all barcoded for scan to pack.

- Group special offers (most popular products) into a single batch type.

- Batch shipments for products that require a cherry-picker or fork-lift to allow trained staff to work on those batches.

- Prioritise perishable goods e.g. food

- Bigger batches on a Monday morning to include orders that came in over the weeked.

Note If there are no pickers working in the warehouse e.g. on weekends, then the batch schedule should not be running, but on a Monday morning a customer may want batches with a higher minimum size - rather than chunking up into batches of a smaller size - in order to clear the weekend orders.

Batching Shipments

Three things need to happen in order for shipments to be grouped within a batch:

- the shipment picking mode needs to be set to

batch. Shipments that don't have this picking mode set will not be considered eligible for batch processing. - a shipment needs to be associated with a Batch Type. The Batch Type contains the configuration that will be used to control aspects of batch creation and processing. For example, the Batch Type holds configuration for the minimum and maximum sizes of the batch.

- a batch needs to be created. This will group a number of pickable shipments together. All of the shipments in the created batch will share the batch type associated with with the batch.*

A picker is generally responsible for picking and completing a batch. In paper-based picking the batches are printed off at the print server and assigned to the pickers (usually by a warehouse manager). For handheld scanners, the pickers are presented with the next batch available (or can scroll down to select another one).

Batch Configuration

The most relevant properties to understand the purpose of a batch selection script are:

- Reference - this is the string value that is returned from a batch selection script

- Sort Indicator - an optional integer value to prioritise batches in a handheld pick or the order in which batches are presented in the GUI to print off on the print server. (TBC)

- Min Batch Size - the minimum number of shipments before the batch is created e.g 10 would mean there has to be at least 10 shipments that qualify for a batch (via the batch selection script) before the batch is created for picking.

- Max Batch Size - the maximum number of shipments that can be processed - a limitation might be the capacity of the pickers' cart or tote and the ability of a packer to find the products picke into a mixed, multiline cart.

- Report Picking Sort - the order in which shipments within a single batch are picked e.g. location.sortIndicator (prioritised by picking locations)

- Shipment Sort Expression - the order in which shipments are assigned to a batch e.g. shipment.priority, shipment.earliestShipDate (higher priority shipments oldest shipments are first in the batch to be presented for picking).

Batch Ejection

If a shipment is part of a batch, but for some reason it cannot be processed as part of the batch, then it will need to be ejected, or taken out of the batch.

One cause for ejecting a shipment from a batch is when a short pick occurs. This is when it turns out during picking that some of the stock that has been earmarked for a shipment is either not present or not in a condition suitable for despatch.

One question that arises is what happens to a shipment when it is ejected from a batch. By default, the following will occur:

- if all of the items for the shipment are in the same mobile picking location, then the shipment will be marked as

packable. At this point there is no reason why the shipments cannot be handed to the packer. - if all of the items are in pickable storage locations, then no change is required. Here, it should be possible to introduce the shipment to a new batch without having to reassign picking locations.

- if some of the items have been picked (and are present in mobile locations), while some of the items are still awaiting picking from storage locations, then the shipment will be reset. Effectictively, the shipment will be returned to the start of the workflow.

Note that a shipment can be ejected from a batch manually through user action, and by the system. If a shipment is cancelled, it will automatically be ejected from the batch if it is currently undergoing batch picking.

Handheld Picking

Handheld picking involves the use of handheld terminals (HHTs) to support picking of shipments. Handheld picking is typically used for picking batches, although it is by no means exclusively limited to this. Handheld picking can be used for picking individual shipments, as well as for interleaved task picking, described earlier in this chapter.

Batch Picking Strategies

When doing a batch pick, the picker will pick items from storage into a mobile location (cart, trolley, etc) before handing items to the packer. The trolley can itself be subdivided, allowing for a more fine-grained pick which makes it easier for the packer to find the items that have been picked.

There are three main batch picking strategies that can be used:

| Name | Description | Pros | Cons |

|---|---|---|---|

| Single Mobile Location | All picked items go into a single mobile location | Easy to set up | Harder for packer to find items as they all end up in a single location |

| System-directed Subdivided | The system will associate batch with trolley, but individual shipments will be assigned to sub-locations within the trolley | Very easy for packer as all of the items for shipment are already consolidated | Not as good at handling locations with very different product sizes |

| User-directed Subdivided | The user will scan each item into a subdivision of the trolley, but shipments stock for shipments won't be grouped | Very easy for packer as all of the items for shipment are already consolidated | Packer still needs to do a bit of work to 'group' shipment stock |

In the first iteration of an implementation, using a single mobile location may be the way to go as the setup is easier. If products are small or homogenous, the system-directed subdivided cart offers real efficiency gains. If products vary significantly in size, the user-directed subdivisions provide a balance between efficiency and a solution for the practical diffculties posed by product size differences.