Stock Moves

Stock Moves

Stock Move Tasks

OrderFlow features a generalised framework for managing stock moves within the warehouse. Stock Move Tasks can be set up for a variety of purposes.

An important application of this is in replenishment, described above. OrderFlow uses its task framework to drive the replenishment process.

The task definition that backs this task contains the configuration that dictates how OrderFlow creates the background replenishment task. In this case, the task uses the "Incremental Target-centric" strategy. This uses a "background picking replenishment strategy" report to populate a map of products to quantities of each product that requires replenishment. This map is then used to create the required stock move lines in the task, based on available stock in the warehouse.

Task configuration is a complex area - more details on this subject can be found in the Scripting and Advanced Configuration Guide.

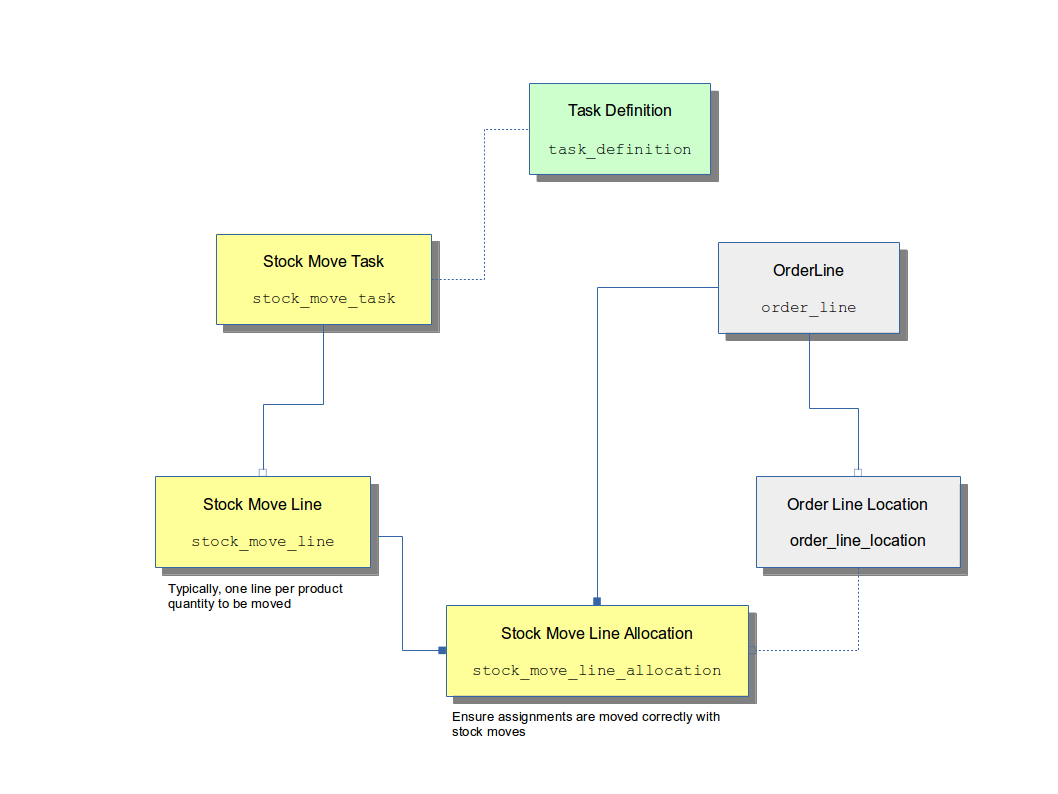

The system entities involved in Stock Move Tasks are shown below.

Task Creation

Depending on the particular task, the way it is being used and the process that it is supporting, tasks can either be created on their own or to support a specific process.

For example, an incoming to consolidation task is created to support the movement of a single line of received stock (for just one product) into one or more consolidation locations, each fulfilling the role of temporary holding location for stock required for a single shipment. In this case, the task creation takes place as part of a larger integrated operation which may involve the receipt of a complete delivery.

Similarly, a batch picking task is created to support the picking of a single shipment batch or 'wave'. Here, the task defines the specific lines that need to be picked from storage locations into a mobile target location, such as a tote, cart or trolley.

Tasks that are simply designed to support stock moves from one set of locations to another tend to be created and processed on a standalone basis. Examples of these types of tasks are putaway, replenishment and storage to consolidation tasks.

For tasks that are created on a standalone basis, this creation can either take place manually via the GUI, or automatically via a scheduled job.

Task Completion

Task completion is the process of carrying out the stock moves identified by the task lines. OrderFlow supports two modes of completion for tasks: paper-driven and via a handheld terminal.

The obvious advantages of the desktop-based approach is that it is cheap and simple to implement. However, it does have a couple of disadvantages:

- because none of the items moved are physically scanned during the stock move, it does not a perfect accuracy.

- because all of the stock changes are applied in a single operation on the system after all of the physical moves have been applied for some lines there may be a delay between the time of the physical stock move and the point at which these are reflected on the system.

Standalone tasks are typically completed by selecting a task from the TASK handheld menu. For tasks that are integrated into other workflows, there is normally a transition from one of the other handheld screens into a task picking or putaway sequence.

The processing mode task configuration property determines for each task definition whether handheld or desktop-based processing is supported for that task.

Task States

| Name | Description |

|---|---|

| created | "The task has been created but is not yet ready for processing. This may be because the task lines are still being populated." |

| ready | "The task is ready for processing." |

| applied | "All lines in the task have been completed, and all associated stock moves have been recorded on the system." |

| in progress | "Task processing is under way. The task moves to this state once a handheld user starts working on a task." |

| accepted | "Used to record the fact that the task has been accepted. This is used to take the task off the queue of open tasks with the intention of completion it." |

| printed | "The paperwork for the task has been printed. This needs to take place before the physical stock moves associated with the lines can take place. Once this has taken place, the user can record the stock moves, with an optional step to record modifications prior to committing the stock changes on the system." |

Replenishment

Replenishment is the term used to describe the process of moving stock from storage locations to pickable locations within a warehouse.

Storage locations will typically be locations that are less accessible than pickable locations, for example pallet racking that requires a fork-lift or an aerial work platform (or "man-up") to reach. Retrieving stock from these locations takes more time and can be more difficult. Additionally, specialist qualifications may be required to use the equipment to reach them.

Pickable locations, on the other hand, will typically be more easily accessible to picking staff.

The timing of when to replenish stock is influenced by several factors, including the capacity of the pickable locations, the 'box size' of the stock, the time it takes to access the replenishment locations, and most of all, the outstanding order line requirement.

OrderFlow supports 'priority' replenishment tasks and 'background' replenishment tasks.

Priority Replenishment will move whatever stock is required by existing shipments from bulk storage locations into picking locations. The scope of priority replenishment tasks is restricted to the items needed to by existing shipments with the state 'pending move'. It allows shipments that already exist within OrderFlow to be progressed

Background Replenishment is used to replenish the picking faces by moving stock out of bulk storage locations. An OrderFlow product definition can be given a 'Picking Threshold' value and a 'Picking Location Max' value. When the stock available in the picking face falls below the 'Picking Threshold' the background total quantity available in the pick face up to the value defined in 'Picking Location Max'.

The difference between background and priority replenishment tasks is encapsulated in the report that each task definition uses. The background replenishment uses "background picking replenishment strategy" report, the priority replenishment task uses the "priority location picking replenishment strategy" report.