Pack Setup

Packing Setup

Once courier integration, courier selection and picking have been taken care, of the next stage in the implementation is to address Packing.

To a large extent the decisions on picking and packing influence each other, and hence need to be made together.

Set Up Packing-related Configuration

There is some basic packing-related configuration that needs to be applied.

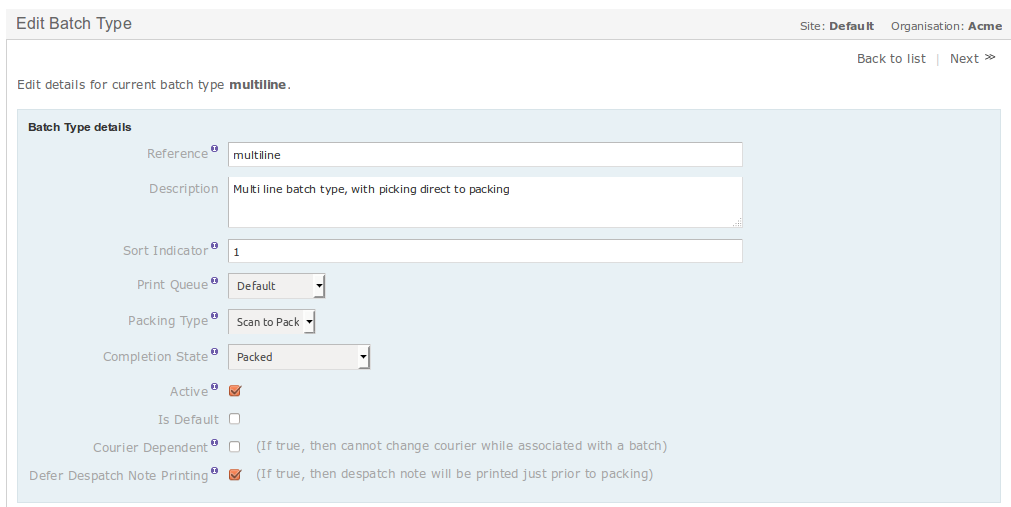

Typically, for each batch type, the 'Defer Despatch Note Printing' option will need to be set. This indicates that printing of despatch notes will take place at the packing desk. Also, it is more common to the 'Courier Dependent' option unticked; this option will only apply when it is important that only shipments with a particular courier appear as part of a batch.

Scan to pack is enabled by default. This requires the user to scan each product at the packing desk before allowing it to be packed. This behaviour can be modified by setting the 'bypass.product.scan' property to true.

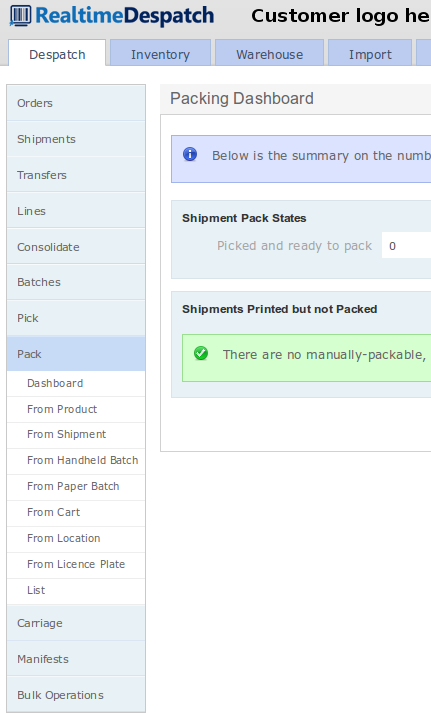

The packing screen for shipments can be accessed via a number of routes. The appropriate starting point for initiating a packing operation will be determined by the nature of the picking mechanism used.

When handheld picking is used, the most common starting point is the Despatch -> Pack -> From Location. Once this has been decided, it is best to hide the menu options that will not be used.

Details on how to hide unwanted menus can be found in the How to hide menus HowTo Wiki page.

Verify Scan to Pack of Picked Shipments

This follows end to end test of picking. The aim here is to ensure that the full packing workflow can be completed:

From the Pack menu it should be possible to ensure that:

- the identification of the batch or shipment being packed takes place

- individual items can be scanned if necessary prior to reaching the packing screen

- any necessary paperwork printing operations are completed

- the shipment can be marked as packed using the 'Pack' button

The customer should also understand when a shipment is locked for packing, and how to unlock the shipment.

The customer should also be comfortable with the mechanism for selecting a different courier or service at the packing screen, if this is to be supported.

Verify Despatch Note Printing

The aim of this part of the implementation is to ensure that despatch note printing is occurring correctly.

This of course relies on the packing workstation being set up correctly (see the Workstation Printing chapter) and the correct workstation being selected.

You should at this point cover the options for auto-printing, and turn these on and verify if appropriate.

Relevant Application Properties

| Name | Description |

|---|---|

| despatchnote.autoprint.enabled | Whether automatic printing of despatch notes or labels is supported. |

| despatch.autoprint.operations | An optionally scriptable property which determines which packing desk operations are automatically run at packing desk without user intervention. |

Verify Label Printing

The next step in the integration is to ensure that the label printing is occurring as expected.

Once again, we want to make sure that the courier label is printed as expected.

Note that the courier integration testing should already have verified the label generation mechanism for a relevant combination of shipments, so that this point we are really just sanity checking the end to end workflow.

Multiple Courier Implementations

As printing mechanisms tend to vary by courier integration, this step needs to be repeated for each courier integration.

Again, the auto-printing discussion from the previous section applies. Note that it may not be applicable to auto-print labels for all carriers in all situations, so the choice here should be verified.

Verify Package Division

The customer needs to understand how to perform package division at the packing desk.

This will normally be necessary if more than one package (also called parcel or piece) is required to despatch the shipment. (In some cases, OrderFlow can be set up to divide shipments into packages automatically based on a maximum weight threshold).

Verify for each courier that can be package split, and that you are able to print the relevant multi-package labels. If necessary also reprint despatch notes.

The customer should also understand the difference between shipment splitting (which results in separate shipments or consignments) and package division (where multiple parcels are sent out as part of the same shipment).

Multiple Courier Implementations

The supported mechanism for division of shipments into packages varies by courier integration. For this reason, it is necessary to verify package division separately for each courier integration used in the implementation.